Page 747 - Mechatronics with Experiments

P. 747

PROGRAMMABLE MOTION CONTROL SYSTEMS 733

d θ

(l )

dt 2 correct

l knife d θ l

cut-to-mark

d (l )

dt 1 l web a θ

l

cut

Desired cut point

sensor

d

d dt (l web )

dt (l )

1

l l knife

knife

contact non-contact

θ correct

d d (l )

dt (l ) dt tool

2

Z 1 Z 2

l l

knife knife

contact non-contact

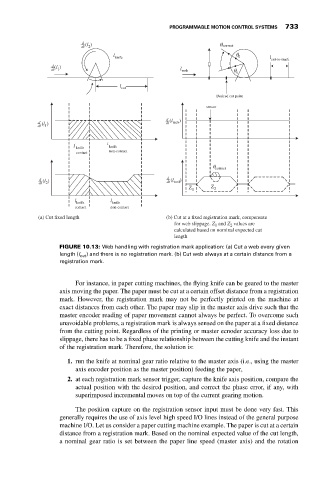

(a) Cut fixed length (b) Cut at a fixed registration mark, compensate

for web slippage. Z 1 and Z 2 values are

calculated based on nominal expected cut

length

FIGURE 10.13: Web handling with registration mark application: (a) Cut a web every given

length (l cut ) and there is no registration mark. (b) Cut web always at a certain distance from a

registration mark.

For instance, in paper cutting machines, the flying knife can be geared to the master

axis moving the paper. The paper must be cut at a certain offset distance from a registration

mark. However, the registration mark may not be perfectly printed on the machine at

exact distances from each other. The paper may slip in the master axis drive such that the

master encoder reading of paper movement cannot always be perfect. To overcome such

unavoidable problems, a registration mark is always sensed on the paper at a fixed distance

from the cutting point. Regardless of the printing or master ecnoder accuracy loss due to

slippage, there has to be a fixed phase relationship between the cutting knife and the instant

of the registration mark. Therefore, the solution is:

1. run the knife at nominal gear ratio relative to the master axis (i.e., using the master

axis encoder position as the master position) feeding the paper,

2. at each registration mark sensor trigger, capture the knife axis position, compare the

actual position with the desired position, and correct the phase error, if any, with

superimposed incremental moves on top of the current gearing motion.

The position capture on the registration sensor input must be done very fast. This

generally requires the use of axis level high speed I/O lines instead of the general purpose

machine I/O. Let us consider a paper cutting machine example. The paper is cut at a certain

distance from a registration mark. Based on the nominal expected value of the cut length,

a nominal gear ratio is set between the paper line speed (master axis) and the rotation