Page 752 - Mechatronics with Experiments

P. 752

738 MECHATRONICS

Non_Contact_Phase:

change gear ratio of tool (slave) to web (master) to

ratios defined by

z = gear_ratio_noncontact_num / gear_ratio_

noncontact_den

Return

Registration_Mark_Phase_Adjustment:

Get the position of the tool captured on registration

mark with high speed capture

Compare the actual position to the position desired

for proper phase

Command additional move (Position desired - Position

captured) to complete fast

Return

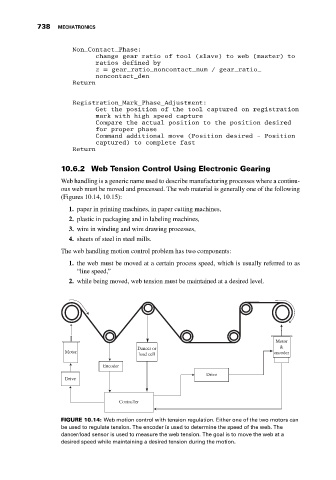

10.6.2 Web Tension Control Using Electronic Gearing

Web handling is a generic name used to describe manufacturing processes where a continu-

ous web must be moved and processed. The web material is generally one of the following

(Figures 10.14, 10.15):

1. paper in printing machines, in paper cutting machines,

2. plastic in packaging and in labeling machines,

3. wire in winding and wire drawing processes,

4. sheets of steel in steel mills.

The web handling motion control problem has two components:

1. the web must be moved at a certain process speed, which is usually referred to as

“line speed,”

2. while being moved, web tension must be maintained at a desired level.

Motor

Dancer or &

Motor encoder

load cell

Encoder

Drive

Drive

Controller

FIGURE 10.14: Web motion control with tension regulation. Either one of the two motors can

be used to regulate tension. The encoder is used to determine the speed of the web. The

dancer/load sensor is used to measure the web tension. The goal is to move the web at a

desired speed while maintaining a desired tension during the motion.