Page 100 - Servo Motors and Industrial Control Theory -

P. 100

5.2 Stepping Motors with Small Step Angle 93

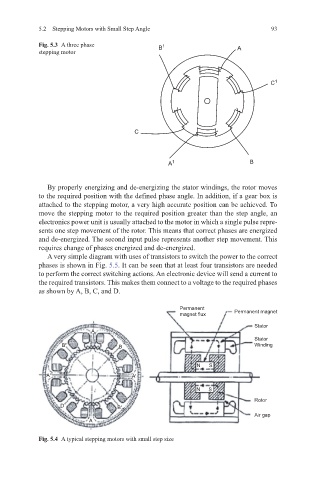

Fig. 5.3 A three phase B 1

stepping motor A

C 1

C

A 1 B

By properly energizing and de-energizing the stator windings, the rotor moves

to the required position with the defined phase angle. In addition, if a gear box is

attached to the stepping motor, a very high accurate position can be achieved. To

move the stepping motor to the required position greater than the step angle, an

electronics power unit is usually attached to the motor in which a single pulse repre-

sents one step movement of the rotor. This means that correct phases are energized

and de-energized. The second input pulse represents another step movement. This

requires change of phases energized and de-energized.

A very simple diagram with uses of transistors to switch the power to the correct

phases is shown in Fig. 5.5. It can be seen that at least four transistors are needed

to perform the correct switching actions. An electronic device will send a current to

the required transistors. This makes them connect to a voltage to the required phases

as shown by A, B, C, and D.

Permanent

magnet flux Permanent magnet

Stator

A

Stator

B' B Winding

N S

A' A'

N S

Rotor

D B'

Air gap

A

Fig. 5.4 A typical stepping motors with small step size