Page 195 - Icon Ridge Hardware & Fixing Technology Catalog

P. 195

Fixing technology

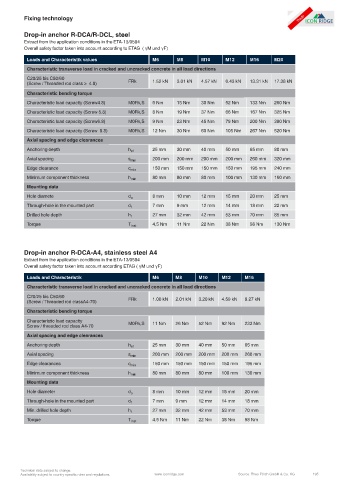

Drop-in anchor R-DCA/R-DCL, steel

Extract from the application conditions in the ETA-13/0584

Overall safety factor taken into account according to ETAG ( γM und γF)

Loads and Characteristik values M6 M8 M10 M12 M16 M20

Characteristic transverse load in cracked and uncracked concrete in all load directions

C20/25 bis C50/60

(Screw / Threaded rod class ≥ 4.8) FRk 1.52 kN 3.01 kN 4.57 kN 6.43 kN 13.31 kN 17.38 kN

Characteristic bending torque

Characteristic load capacity (Screw4.8) M0Rk,S 6 Nm 15 Nm 30 Nm 52 Nm 133 Nm 260 Nm

Characteristic load capacity (Screw 5.8) M0Rk,S 8 Nm 19 Nm 37 Nm 66 Nm 167 Nm 325 Nm

Characteristic load capacity (Screw6.8) M0Rk,S 9 Nm 23 Nm 45 Nm 79 Nm 200 Nm 390 Nm

Characteristic load capacity (Screw 8.8) M0Rk,S 12 Nm 30 Nm 60 Nm 105 Nm 267 Nm 520 Nm

Axial spacing and edge clearances

Anchoring depth h ef 25 mm 30 mm 40 mm 50 mm 65 mm 80 mm

Axial spacing s min 200 mm 200 mm 200 mm 200 mm 260 mm 320 mm

Edge clearance c min 150 mm 150 mm 150 mm 150 mm 195 mm 240 mm

Minimum component thickness h min 80 mm 80 mm 80 mm 100 mm 130 mm 160 mm

Mounting data

Hole diamete d o 8 mm 10 mm 12 mm 15 mm 20 mm 25 mm

Through-hole in the mounted part d f 7 mm 9 mm 12 mm 14 mm 18 mm 22 mm

Drilled hole depth h 1 27 mm 32 mm 42 mm 53 mm 70 mm 85 mm

Torque T inst 4,5 Nm 11 Nm 22 Nm 38 Nm 98 Nm 130 Nm

Drop-in anchor R-DCA-A4, stainless steel A4

Extract from the application conditions in the ETA-13/0584

Overall safety factor taken into account according ETAG ( γM und γF)

Loads and Characteristik M6 M8 M10 M12 M16

Characteristic transverse load in cracked and uncracked concrete in all load directions

C20/25 bis C50/60 FRk 1.00 kN 2.01 kN 3.20 kN 4.59 kN 8.27 kN

(Screw / Threaded rod classA4-70)

Characteristic bending torque

Characteristic load capacity M0Rk,S 11 Nm 26 Nm 52 Nm 92 Nm 233 Nm

Screw / threaded rod class A4-70

Axial spacing and edge clearances

Anchoring depth h ef 25 mm 30 mm 40 mm 50 mm 65 mm

Axial spacing s min 200 mm 200 mm 200 mm 200 mm 260 mm

Edge clearances c min 150 mm 150 mm 150 mm 150 mm 195 mm

Minimum component thickness h min 80 mm 80 mm 80 mm 100 mm 130 mm

Mounting data

Hole diameter d o 8 mm 10 mm 12 mm 15 mm 20 mm

Through-hole in the mounted part d f 7 mm 9 mm 12 mm 14 mm 18 mm

Min. drilled hole depth h 1 27 mm 32 mm 42 mm 53 mm 70 mm

Torque T inst 4.5 Nm 11 Nm 22 Nm 38 Nm 98 Nm

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 195