Page 199 - Icon Ridge Hardware & Fixing Technology Catalog

P. 199

Fixing technology

Hollow ceiling anchor, steel

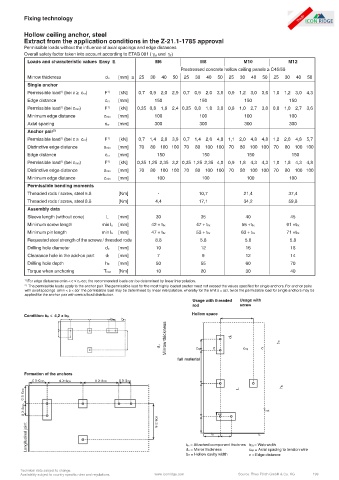

Extract from the application conditions in the Z-21.1-1785 approval

Permissible loads without the influence of axial spacings and edge distances

Overall safety factor taken into account according to ETAG 001 ( γ M und γ F )

Loads and characteristic values Easy E M6 M8 M10 M12

Prestressed concrete hollow ceiling panels ≥ C45/55

Mirrow thickness du [mm] ≥ 25 30 40 50 25 30 40 50 25 30 40 50 25 30 40 50

Single anchor

Permissible load (bei c ≥ ccr) F 1) [kN] 0,7 0,9 2,0 2,9 0,7 0,9 2,0 3,6 0,9 1,2 3,0 3,6 1,0 1,2 3,0 4,3

1)

Edge distance ccr [mm] 150 150 150 150

1)

Permissible load (bei cmin) F 1) [kN] 0,35 0,8 1,8 2,4 0,35 0,8 1,8 3,0 0,8 1,0 2,7 3,0 0,8 1,0 2,7 3,6

Minimum edge distance cmin [mm] 100 100 100 100

Axial spacing scr [mm] 300 300 300 300

Anchor pair 2)

Permissible load (bei c ≥ ccr) F 1) [kN] 0,7 1,4 2,6 3,9 0,7 1,4 2,6 4,8 1,1 2,0 4,8 4,8 1,2 2,0 4,8 5,7

1)

Distinctive edge distance smin [mm] 70 80 100 100 70 80 100 100 70 80 100 100 70 80 100 100

Edge distance ccr [mm] 150 150 150 150

1)

Permissible load (bei cmin) F 1) [kN] 0,35 1,25 2,35 3,2 0,35 1,25 2,35 4,0 0,9 1,8 4,3 4,3 1,0 1,8 4,3 4,8

Distinctive edge distance smin [mm] 70 80 100 100 70 80 100 100 70 80 100 100 70 80 100 100

Minimum edge distance cmin [mm] 100 100 100 100

Permissible bending moments

Threaded rods / screw, steel 5.8 [Nm] - 10,7 21,4 37,4

Threaded rods / screw, steel 8.8 [Nm] 4,4 17,1 34,2 59,8

Assembly data

Sleeve length (without cone) L [mm] 30 35 40 45

Minimum screw length min ls [mm] 42 + tfix 47 + tfix 55 +tfix 61 +tfix

Minimum pin length min lb [mm] 47 + tfix 53 + tfix 63 + tfix 71 +tfix

Requested steel strength of the screws / threaded rods 8.8 5.8 5.8 5.8

Drilling hole diameter do [mm] 10 12 16 18

Clearance hole in the add-on part df [mm] 7 9 12 14

Drilling hole depth h0 [mm] 50 55 60 70

Torque when anchoring Tinst [Nm] 10 20 30 40

1) For edge distances cmin < c ≤ ccr ccr, the recommended loads can be determined by linear interpolation.

2) The permissible loads apply to the anchor pair. The permissible load for the most highly loaded anchor must not exceed the values specified for single anchors. For anchor pairs

with axial spacings smin < s < scr the permissible load may be determined by linear interpolation, whereby for the limit s = scr, twice the permissible load for single anchors may be

applied for the anchor pair with central load distribution.

Usage with threaded Usage with

rod screw

Hollow space

Condition: bH ≤ 4,2 x bSt

bSt bH

Mirrow thickness du tfix

du cSp c cSp c

full material

Formation of the anchors

c ≥ cmin s ≥ sCR s ≥ sCR s ≥ smin

ho

L

c ≥ cmin

s ≥ smin Tinst Tinst

s ≥ sCR

Longitudinal joint tfix = Attached component thicknes bSt = Web width

lb

ls

du = Mirror thickness

bH = Hollow cavity width cSp = Axial spacing to tension wire

c = Edge distance

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 199