Page 415 - Icon Ridge Maintenance & Service Catalog

P. 415

Drilling, Milling, Tapping and Threading

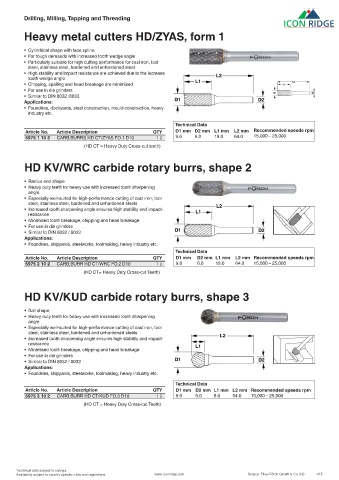

Heavy metal cutters HD/ZYAS, form 1

• Cylindrical shape with face spline

• For tough demands with increased tooth wedge angle

• Particularly suitable for high cutting performance for cast iron, tool

steel, stainless steel, hardened and unhardened steel

• High stability and impact resistance are achieved due to the increase

tooth wedge angle

• Chipping, spalling and head breakage are minimised

• For use in die grinders

• Similar to DIN 8032 /8033

Applications:

• Foundries, dockyards, steel construction, mould construction, heavy

industry etc.

Technical Data

Article No. Article Description QTY D1 mm D2 mm L1 mm L2 mm Recommended speeds rpm

5975 1 10 2 CARB.BURRS HD CT/ZYAS FO.1 D10 1 ü 9.6 6.0 19.0 64.0 15,000 – 25,000

(HD CT = Heavy Duty Cross-cut teeth)

HD KV/WRC carbide rotary burrs, shape 2

• Radius end shape

• Heavy duty teeth for heavy use with increased tooth sharpening

angle

• Especially well-suited for high-performance cutting of cast iron, tool

steel, stainless steel, hardened and unhardened steels

• Increased tooth sharpening angle ensures high stability and impact-

resistance

• Minimised tooth breakage, chipping and head breakage

• For use in die grinders

• Similar to DIN 8032 / 8033

Applications:

• Foundries, shipyards, steelworks, toolmaking, heavy industry etc.

Technical Data

Article No. Article Description QTY D1 mm D2 mm L1 mm L2 mm Recommended speeds rpm

5975 2 10 2 CARB.BURR HD CT/WRC FO.2 D10 1 ü 9.6 6.0 19.0 64.0 15,000 – 25,000

(HD CT= Heavy Duty Cross-cut Teeth)

HD KV/KUD carbide rotary burrs, shape 3

• Ball shape

• Heavy duty teeth for heavy use with increased tooth sharpening

angle

• Especially well-suited for high-performance cutting of cast iron, tool

steel, stainless steel, hardened and unhardened steels

• Increased tooth sharpening angle ensures high stability and impact-

resistance

• Minimised tooth breakage, chipping and head breakage

• For use in die grinders

• Similar to DIN 8032 / 8033

Applications:

• Foundries, shipyards, steelworks, toolmaking, heavy industry etc.

Technical Data

Article No. Article Description QTY D1 mm D2 mm L1 mm L2 mm Recommended speeds rpm

5975 3 10 2 CARB.BURR HD CT/KUD FO.3 D10 1 ü 9.6 6.0 8.0 54.0 15,000 – 25,000

(HD CT = Heavy Duty Cross-cut Teeth)

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 415