Page 412 - Icon Ridge Maintenance & Service Catalog

P. 412

Drilling, Milling, Tapping and Threading

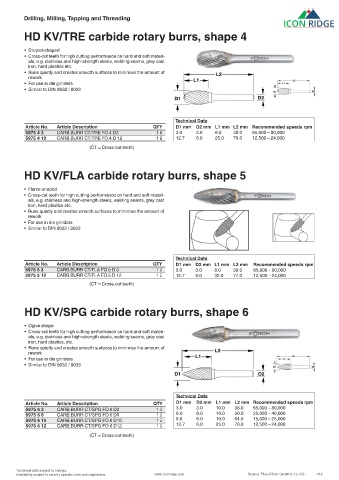

HD KV/TRE carbide rotary burrs, shape 4

• Droplet-shaped

• Cross-cut teeth for high cutting performance on hard and soft materi-

als, e.g. stainless and high-strength steels, welding seams, grey cast

iron, hard plastics etc.

• Runs quietly and creates smooth surfaces to minimise the amount of

rework

• For use in die grinders

• Similar to DIN 8032 / 8033

Technical Data

Article No. Article Description QTY D1 mm D2 mm L1 mm L2 mm Recommended speeds rpm

5975 4 3 CARB.BURR CT/TRE FO.4 D3 1 ü 3.0 3.0 6.0 38.0 65,000 – 80,000

5975 4 12 CARB.BURR CT/TRE FO.4 D 12 1 ü 12.7 6.0 25.0 70.0 12,500 – 24,000

(CT = Cross-cut teeth)

HD KV/FLA carbide rotary burrs, shape 5

• Flame-shaped

• Cross-cut teeth for high cutting performance on hard and soft materi-

als, e.g. stainless and high-strength steels, welding seams, grey cast

iron, hard plastics etc.

• Runs quietly and creates smooth surfaces to minimise the amount of

rework

• For use in die grinders

• Similar to DIN 8032 / 8033

Technical Data

Article No. Article Description QTY D1 mm D2 mm L1 mm L2 mm Recommended speeds rpm

5975 5 3 CARB.BURR CT/FLA FO.5 D 3 1 ü 3.0 3.0 8.0 38.0 65,000 – 80,000

5975 5 12 CARB.BURR CT/FLA FO.5 D 12 1 ü 12.7 6.0 32.0 77.0 12,500 – 24,000

(CT = Cross-cut teeth)

HD KV/SPG carbide rotary burrs, shape 6

• Ogive shape

• Cross-cut teeth for high cutting performance on hard and soft materi-

als, e.g. stainless and high-strength steels, welding seams, grey cast

iron, hard plastics, etc.

• Runs quietly and creates smooth surfaces to minimise the amount of

rework

• For use in die grinders

• Similar to DIN 8032 / 8033

Technical Data

Article No. Article Description QTY D1 mm D2 mm L1 mm L2 mm Recommended speeds rpm

5975 6 3 CARB.BURR CT/SPG FO.6 D3 1 ü 3.0 3.0 10.0 38.0 65,000 – 80,000

5975 6 6 CARB.BURR CT/SPG FO.6 D6 1 ü 6.0 6.0 18.0 50.0 25,000 – 40,000

5975 6 10 CARB.BURR CT/SPG FO.6 D10 1 ü 9.6 6.0 19.0 64.0 15,000 – 25,000

5975 6 12 CARB.BURR CT/SPG FO.6 D12 1 ü 12.7 6.0 25.0 70.0 12,500 – 24,000

(CT = Cross-cut teeth)

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 412