Page 387 - Industrial Tools Catalog (1)

P. 387

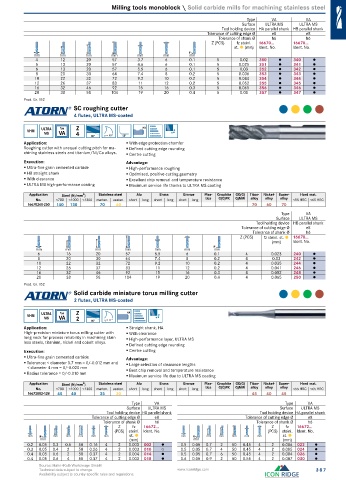

Milling tools monoblock \ Solid carbide mills for machining stainless steel

Type VA VA

Surface ULTRA MS ULTRA MS

Tool holding device HA parallel shank HB parallel shank

Tolerance of cutting edge Ø e8 e8

Tolerance of shank Ø h6 h6

Z (PCS) fz steinl. 16670... 16670...

st. (mm) Ident. No. Ident. No.

mm mm mm mm mm mm mm

4 12 20 57 3.7 6 0.1 5 0.02 350 ● 340 ●

5 13 20 57 4.6 6 0.1 5 0.025 351 ● 341 ●

6 13 20 57 5.5 6 0.1 5 0.03 352 ● 342 ●

8 20 30 64 7.4 8 0.2 5 0.036 353 ● 343 ●

10 22 32 72 9.2 10 0.2 5 0.044 354 ● 344 ●

12 26 37 83 11 12 0.2 5 0.052 355 ● 345 ●

16 32 46 92 15 16 0.3 5 0.065 356 ● 346 ●

20 38 58 104 19 20 0.4 5 0.08 357 ● 347 ●

Prod. Gr. 152

SC roughing cutter

4 flutes, ULTRA MS-coated

ULTRA Typ Z HB

VHM VA

MS 4 γ = 10° 45°

Application: With edge protection chamfer

Roughing cutter with unequal cutting pitch for ma- Defined cutting edge rounding

chining stainless steels and titanium/Ni/Co alloys. Centre cutting

Execution: Advantage:

Ultra-fine grain cemented carbide High-performance roughing

HB straight shank Optimised, positive cutting geometry

With clearance Excellent chip removal and temperature resistance

ULTRA MS high-performance coating Maximum service life thanks to ULTRA MS coating

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16670240-250 140 130 70 60 70 60 70

Type VA

Surface ULTRA MS

Tool holding device HB parallel shank

Tolerance of cutting edge Ø e8

Tolerance of shank Ø h6

Z (PCS) fz steinl. st. 16670...

(mm) Ident. No.

mm mm mm mm mm mm mm

6 16 20 57 5.5 6 0.1 4 0.023 240 ●

8 20 30 64 7.4 8 0.2 4 0.03 242 ●

10 22 32 72 9.2 10 0.2 4 0.035 244 ●

12 26 37 83 11 12 0.2 4 0.041 246 ●

16 32 46 92 15 16 0.3 4 0.052 248 ●

20 38 58 104 19 20 0.4 4 0.065 250 ●

Prod. Gr. 152

Solid carbide miniature torus milling cutter

2 flutes, ULTRA MS-coated

VHM ULTRA Typ Z HA

MS VA 2 γ = 11°

Application: Straight shank, HA

High-precision miniature torus milling cutter with With clearance

long neck for process reliability in machining stain- High-performance layer, ULTRA MS

less steels, titanium, nickel and cobalt alloys.

Defined cutting edge rounding

Execution: Centre cutting

Ultra-fine grain cemented carbide Advantage:

Tolerance: < diameter 0.7 mm = 0/-0.012 mm and Large selection of clearance lengths

< diameter 4 mm = 0/-0.020 mm Best chip removal and temperature resistance

Radius tolerance = 0/-0.010 mm Maximum service life due to ULTRA MS coating

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16672002-128 45 40 35 30 45 40 45

Type VA Type VA

Surface ULTRA MS Surface ULTRA MS

Tool holding device HA parallel shank Tool holding device HA parallel shank

Tolerance of cutting edge Ø e8 Tolerance of cutting edge Ø e8

Tolerance of shank Ø h6 Tolerance of shank Ø h6

Z fz 16672... Z fz 16672...

(PCS) steinl. Ident. No. (PCS) steinl. Ident. No.

mm mm mm mm mm mm st. mm mm mm mm mm mm st.

mm (mm) mm (mm)

0.2 0.05 0.3 0.5 50 0.16 4 2 0.003 002 ● 0.5 0.05 0.7 2 50 0.45 4 2 0.006 022 ●

0.3 0.05 0.4 2 50 0.26 4 2 0.003 010 ○ 0.5 0.05 0.7 4 50 0.45 4 2 0.005 024 ●

0.4 0.05 0.6 2 50 0.37 4 2 0.004 014 ● 0.5 0.05 0.7 6 50 0.45 4 2 0.004 026 ●

0.4 0.05 0.6 4 50 0.37 4 2 0.003 018 ● 0.6 0.05 0.9 2 50 0.55 4 2 0.007 030 ●

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 387

Availability subject to country specific rules and regulations.