Page 388 - Industrial Tools Catalog (1)

P. 388

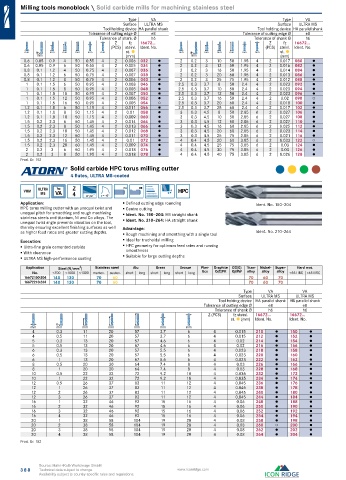

Milling tools monoblock \ Solid carbide mills for machining stainless steel

Type VA Type VA

Surface ULTRA MS Surface ULTRA MS

Tool holding device HA parallel shank Tool holding device HA parallel shank

Tolerance of cutting edge Ø e8 Tolerance of cutting edge Ø e8

Tolerance of shank Ø h6 Tolerance of shank Ø h6

Z fz 16672... Z fz 16672...

(PCS) steinl. Ident. No. (PCS) steinl. Ident. No.

mm mm mm mm mm mm st. mm mm mm mm mm mm st.

mm (mm) mm (mm)

0.6 0.05 0.9 4 50 0.55 4 2 0.006 032 ● 2 0.2 3 10 50 1.95 4 2 0.017 080 ●

0.6 0.05 0.9 6 50 0.55 4 2 0.005 034 ● 2 0.2 3 12 50 1.95 4 2 0.016 082 ●

0.8 0.1 1.2 4 50 0.75 4 2 0.007 036 ● 2 0.2 3 16 50 1.95 4 2 0.014 084 ●

0.8 0.1 1.2 6 50 0.75 4 2 0.007 038 ● 2 0.2 3 20 60 1.95 4 2 0.013 086 ●

0.8 0.1 1.2 8 50 0.75 4 2 0.006 040 ● 2 0.2 3 25 75 1.95 4 2 0.012 088 ●

1 0.1 1.5 6 50 0.95 4 2 0.008 046 ● 2.5 0.3 3.7 8 50 2.4 4 2 0.023 092 ●

1 0.1 1.5 8 50 0.95 4 2 0.008 048 ● 2.5 0.3 3.7 10 50 2.4 4 2 0.023 094 ●

1 0.1 1.5 10 50 0.95 4 2 0.007 050 ● 2.5 0.3 3.7 12 50 2.4 4 2 0.023 096 ●

1 0.1 1.5 12 50 0.95 4 2 0.006 052 ● 2.5 0.3 3.7 16 50 2.4 4 2 0.02 098 ○

1 0.1 1.5 16 50 0.95 4 2 0.005 054 ○ 2.5 0.3 3.7 20 60 2.4 4 2 0.018 100 ●

1.2 0.1 1.8 6 50 1.15 4 2 0.011 056 ● 2.5 0.3 3.7 25 60 2.4 4 2 0.017 102 ●

1.2 0.1 1.8 8 50 1.15 4 2 0.01 058 ● 3 0.3 4.5 8 50 2.85 6 2 0.027 106 ●

1.2 0.1 1.8 10 50 1.15 4 2 0.009 060 ● 3 0.3 4.5 10 50 2.85 6 2 0.027 108 ●

1.5 0.2 2.3 6 50 1.45 4 2 0.014 064 ● 3 0.3 4.5 12 50 2.85 6 2 0.027 110 ●

1.5 0.2 2.3 8 50 1.45 4 2 0.013 066 ● 3 0.3 4.5 16 60 2.85 6 2 0.025 112 ●

1.5 0.2 2.3 10 50 1.45 4 2 0.012 068 ● 3 0.3 4.5 20 60 2.85 6 2 0.023 114 ●

1.5 0.2 2.3 12 50 1.45 4 2 0.011 070 ● 3 0.3 4.5 25 75 2.85 6 2 0.021 116 ●

1.5 0.2 2.3 16 50 1.45 4 2 0.01 072 ● 4 0.4 4.5 20 60 3.85 6 2 0.033 122 ○

1.5 0.2 2.3 20 60 1.45 4 2 0.009 074 ● 4 0.4 4.5 25 75 3.85 6 2 0.03 124 ●

2 0.2 3 6 50 1.95 4 2 0.018 076 ● 4 0.4 4.5 30 75 3.85 6 2 0.03 126 ●

2 0.2 3 8 50 1.95 4 2 0.018 078 ● 4 0.4 4.5 40 75 3.85 6 2 0.026 128 ●

Prod. Gr. 152

Solid carbide HPC torus milling cutter

4 flutes, ULTRA MS-coated

VHM ULTRA Typ Z HA HB HPC

MS VA 4 35°/38° γ = 10°

Application: Defined cutting edge rounding Ident. No. 150–204

HPC torus milling cutter with an unequal twist and Centre cutting

unequal pitch for smoothing and rough machining Ident. No. 150–204: HB straight shank

stainless steels and titanium, Ni and Co alloys. The Ident. No. 210–264: HA straight shank

unequal twist angle prevents vibration on the tool,

thereby ensuring excellent finishing surfaces as well Advantage:

as higher feed rates and greater cutting depths. Rough machining and smoothing with a single tool Ident. No. 210–264

Execution: Ideal for trochoidal milling

Ultra-fine grain cemented carbide HPC geometry for optimum feed rates and running

With clearance smoothness

ULTRA MS high-performance coating Suitable for large cutting depths

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16672150-204 140 130 70 60 70 60 70

16672210-264 140 130 70 60 70 60 70

Type VA VA

Surface ULTRA MS ULTRA MS

Tool holding device HA parallel shank HB parallel shank

Tolerance of cutting edge Ø e8 e8

Tolerance of shank Ø h6 h6

Z (PCS) fz steinl. 16672... 16672...

st. (mm) Ident. No. Ident. No.

mm mm mm mm mm mm mm

4 0.3 11 20 57 3.7 6 4 0.015 210 ● 150 ●

4 0.5 11 20 57 3.7 6 4 0.015 212 ● 152 ●

5 0.3 13 20 57 4.6 6 4 0.02 214 ● 154 ●

5 0.5 13 20 57 4.6 6 4 0.02 216 ● 156 ●

6 0.3 13 20 57 5.5 6 4 0.023 218 ● 158 ●

6 0.5 13 20 57 5.5 6 4 0.023 220 ● 160 ●

6 1 13 20 57 5.5 6 4 0.023 222 ● 162 ●

8 0.5 20 30 64 7.4 8 4 0.03 226 ● 166 ●

8 1 20 30 64 7.4 8 4 0.03 228 ● 168 ●

10 0.5 22 32 72 9.2 10 4 0.035 232 ● 172 ●

10 1 22 32 72 9.2 10 4 0.035 234 ● 174 ●

12 0.5 26 37 83 11 12 4 0.045 236 ● 176 ●

12 1 26 37 83 11 12 4 0.045 238 ● 178 ●

12 2 26 37 83 11 12 4 0.045 240 ● 180 ●

12 3 26 37 83 11 12 4 0.045 244 ● 184 ●

16 1 32 46 92 15 16 4 0.06 248 ● 188 ●

16 2 32 46 92 15 16 4 0.06 250 ● 190 ●

16 3 32 46 92 15 16 4 0.06 252 ● 192 ●

16 4 32 46 92 15 16 4 0.06 254 ● 194 ●

20 1 38 58 104 19 20 4 0.08 258 ● 198 ●

20 2 38 58 104 19 20 4 0.08 260 ○ 200 ●

20 3 38 58 104 19 20 4 0.08 262 ● 202 ●

20 4 38 58 104 19 20 4 0.08 264 ● 204 ●

Prod. Gr. 152

Source: Hahn+Kolb Werkzeuge GmbH

388 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.