Page 28 - Icon Ridge Presents ATORN

P. 28

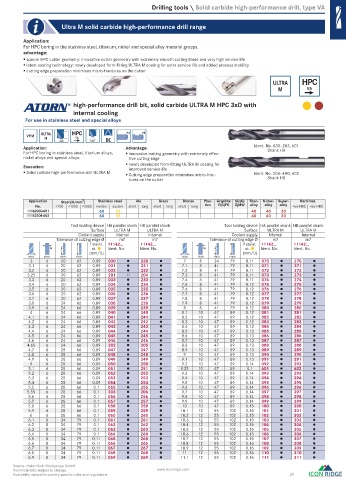

Drilling tools \ Solid carbide high-performance drill, type VA

Ultra M solid carbide high-performance drill range

Application:

For HPC boring in the stainless steel, titanium, nickel and special alloy material groups.

advantage:

special HPC cutter geometry: innovative cutter geometry with extremely smooth cutting blade and very high service life

latest coating technology: newly developed form-fi tting ULTRA M coating for extra service life and added process stability

cutting edge preparation minimises micro-fractures on the cutter

ULTRA HPC

M VA

high-performance drill bit, solid carbide ULTRA M HPC 3xD with

internal cooling

For use in stainless steel and special alloys

VHM ULTRA HPC HA HB

M VA IK

3xD 140°

Application: Advantage: Ident. No. 030–203, 601

Shank HA

For HPC boring in stainless steel, titanium alloys, innovative cutting geometry with extremely eff ec-

nickel alloys and special alloys. tive cutting edge

Execution: newly developed form-fi tting ULTRA M coating for

improved service life

Solid carbide high-performance drill ULTRA M Cutting edge preparation minimises micro-frac- Ident. No. 204–400, 602

tures on the cutter Shank HB

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11142030-601 60 55 40 40 30

11142204-603 60 55 40 40 30

Tool holding device HA parallel shank HB parallel shank Tool holding device HA parallel shank HB parallel shank

Surface ULTRA M ULTRA M Surface ULTRA M ULTRA M

Coolant supply Internal Internal Coolant supply Internal Internal

Tolerance of cutting edge Ø m7 m7 Tolerance of cutting edge Ø m7 m7

f steinl. 11142... 11142... f steinl. 11142... 11142...

h6 st. Ident. No. Ident. No. h6 st. Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

3 6 20 62 0.09 030 230 7 8 34 79 0.11 070 270

3.1 6 20 62 0.09 031 231 7.1 8 41 79 0.11 071 271

3.2 6 20 62 0.09 032 232 7.2 8 41 79 0.11 072 272

3.25 6 20 62 0.09 201 ○ 204 7.3 8 41 79 0.11 073 273

3.3 6 20 62 0.09 033 233 7.4 8 41 79 0.11 074 274

3.4 6 20 62 0.09 034 234 7.5 8 41 79 0.12 075 275

3.5 6 20 62 0.09 035 235 7.6 8 41 79 0.12 076 276

3.6 6 20 62 0.09 036 236 7.7 8 41 79 0.12 077 277

3.7 6 20 62 0.09 037 237 7.8 8 41 79 0.12 078 278

3.8 6 24 66 0.09 038 238 7.9 8 41 79 0.12 079 279

3.9 6 24 66 0.09 039 239 8 8 41 79 0.12 080 280

4 6 24 66 0.09 040 240 8.1 10 47 89 0.12 081 281

4.1 6 24 66 0.09 041 241 8.2 10 47 89 0.12 082 282

4.2 6 24 66 0.09 042 242 8.3 10 47 89 0.12 083 283

4.3 6 24 66 0.09 043 243 8.4 10 47 89 0.13 084 284

4.4 6 24 66 0.09 044 244 8.5 10 47 89 0.13 085 285

4.5 6 24 66 0.09 045 245 8.6 10 47 89 0.13 086 286

4.6 6 24 66 0.09 046 246 8.7 10 47 89 0.13 087 287

4.65 6 24 66 0.09 202 205 8.8 10 47 89 0.13 088 288

4.7 6 28 66 0.09 047 247 8.9 10 47 89 0.13 089 289

4.8 6 28 66 0.09 048 248 9 10 47 89 0.13 090 290

4.9 6 28 66 0.09 049 249 9.1 10 47 89 0.13 091 291

5 6 28 66 0.09 050 250 9.2 10 47 89 0.14 092 292

5.1 6 28 66 0.09 051 251 9.25 10 47 89 0.1 601 602

5.2 6 28 66 0.09 052 252 9.3 10 47 89 0.14 093 293

5.3 6 28 66 0.09 053 253 9.4 10 47 89 0.14 094 294

5.4 6 28 66 0.09 054 254 9.5 10 47 89 0.14 095 295

5.5 6 28 66 0.1 055 255 9.6 10 47 89 0.14 096 296

5.55 6 28 66 0.1 203 206 9.7 10 47 89 0.14 097 297

5.6 6 28 66 0.1 056 256 9.8 10 47 89 0.14 098 298

5.7 6 28 66 0.1 057 257 9.9 10 47 89 0.14 099 299

5.8 6 28 66 0.1 058 258 10 10 47 89 0.15 100 300

5.9 6 28 66 0.1 059 259 10.1 12 55 102 0.15 101 301

6 6 28 66 0.1 060 260 10.2 12 55 102 0.15 102 302

6.1 8 34 79 0.1 061 261 10.3 12 55 102 0.15 103 303

6.2 8 34 79 0.1 062 262 10.4 12 55 102 0.15 104 304

6.3 8 34 79 0.1 063 263 10.5 12 55 102 0.15 105 305

6.4 8 34 79 0.1 064 264 10.6 12 55 102 0.15 106 306

6.5 8 34 79 0.11 065 265 10.7 12 55 102 0.15 107 307

6.6 8 34 79 0.11 066 266 10.8 12 55 102 0.16 108 308

6.7 8 34 79 0.11 067 267 10.9 12 55 102 0.16 109 309

6.8 8 34 79 0.11 068 268 11 12 55 102 0.16 110 310

6.9 8 34 79 0.11 069 269 11.1 12 55 102 0.16 111 311

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 28

0037_EN_2018_KERN[21841696]-e.indd 37 12/17/2018 3:31:05 PM