Page 30 - Icon Ridge Presents ATORN

P. 30

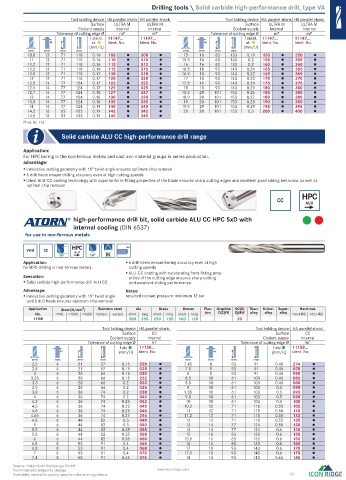

Drilling tools \ Solid carbide high-performance drill, type VA

Tool holding device HA parallel shank HB parallel shank Tool holding device HA parallel shank HB parallel shank

Surface ULTRA M ULTRA M Surface ULTRA M ULTRA M

Coolant supply Internal Internal Coolant supply Internal Internal

Tolerance of cutting edge Ø m7 m7 Tolerance of cutting edge Ø m7 m7

f steinl. 11147... 11147... f steinl. 11147... 11147...

h6 st. Ident. No. Ident. No. h6 st. Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

10.8 12 71 118 0.16 108 308 15 16 83 133 0.19 150 350

11 12 71 118 0.16 110 310 15.5 16 83 133 0.2 155 355

11.2 12 71 118 0.16 112 312 16 16 83 133 0.2 160 360

11.5 12 71 118 0.16 115 315 16.5 18 93 143 0.21 165 365

11.8 12 71 118 0.17 118 318 16.9 18 93 143 0.22 169 369

12 12 71 118 0.17 120 320 17 18 93 143 0.23 170 370

12.2 14 77 124 0.17 122 322 17.5 18 93 143 0.24 175 375

12.5 14 77 124 0.17 125 325 18 18 93 143 0.25 180 380

12.7 14 77 124 0.18 127 327 18.5 20 101 153 0.26 185 385

13 14 77 124 0.18 130 330 18.9 20 101 153 0.27 189 389

13.5 14 77 124 0.18 135 335 19 20 101 153 0.28 190 390

14 14 77 124 0.19 140 340 19.5 20 101 153 0.29 195 395

14.2 16 83 133 0.19 142 342 20 20 101 153 0.3 200 400

14.5 16 83 133 0.19 145 345

Prod. Gr. 113

Solid carbide ALU CC high-performance drill range

Application:

For HPC boring in the non-ferrous metals and cast iron material groups in series production.

advantage:

innovative cutting geometry with 15° twist angle ensures optimum chip removal

6 drill heels ensure drilling accuracy even at high cutting speeds

latest ALU-CC coating technology with superior form-fi tting properties of the blade ensures sharp cutting edges and excellent good sliding behaviour as well as

optimal chip removal

HPC

CC

ALU

high-performance drill bit, solid carbide ALU CC HPC 5xD with

internal cooling ( DIN 6537 )

for use in non-ferrous metals

HPC HA

VHM CC ALU

5xD 135° IK

Application: 6 drill heels ensure boring accuracy even at high

for HPC drilling in non-ferrous metals. cutting speeds

ALU-CC coating with outstanding form-fi tting prop-

Execution: erties of the cutting edge ensures sharp cutting

Solid carbide high-performance drill ALU CC and excellent sliding performance

Advantage: Notes:

innovative cutting geometry with 15° twist angle required coolant pressure: minimum 12 bar

and 6 drill heels ensures optimum chip removal

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11158 380 350 250 190 160 120 90

Tool holding device HA parallel shank Tool holding device HA parallel shank

Surface CC Surface CC

Coolant supply Internal Coolant supply Internal

Tolerance of cutting edge Ø h7 Tolerance of cutting edge Ø h7

f alu 11158... f alu 11158...

h6 (mm/U) Ident. No. h6 (mm/U) Ident. No.

mm mm mm mm mm mm mm mm

2.5 4 21 57 0.15 025 7.45 8 53 91 0.45 274

2.8 4 21 57 0.15 028 7.8 8 53 91 0.45 078

3 6 28 66 0.15 030 8 8 53 91 0.45 080

3.25 6 28 66 0.15 232 8.5 10 61 103 0.45 085

3.3 6 28 66 0.2 033 8.8 10 61 103 0.45 088

3.5 6 28 66 0.2 035 9 10 61 103 0.5 090

3.8 6 36 74 0.2 038 9.35 10 61 103 0.5 093

4 6 36 74 0.2 040 9.8 10 61 103 0.5 098

4.2 6 36 74 0.25 042 10 10 61 103 0.5 100

4.5 6 36 74 0.25 045 10.2 12 71 118 0.55 102

4.6 6 36 74 0.25 046 11 12 71 118 0.55 110

4.65 6 36 74 0.25 246 11.2 12 71 118 0.55 112

4.8 6 44 82 0.3 048 12 12 71 118 0.55 120

5 6 44 82 0.3 050 13 14 77 124 0.55 130

5.5 6 44 82 0.35 055 14 14 77 124 0.6 140

5.8 6 44 82 0.35 058 15 16 83 133 0.6 150

6 6 44 82 0.35 060 15.5 16 83 133 0.6 155

6.5 8 53 91 0.4 065 16 16 83 133 0.6 160

6.8 8 53 91 0.4 068 17 18 93 143 0.6 170

7 8 53 91 0.4 070 17.5 18 93 143 0.6 175

7.4 8 53 91 0.45 074 18 18 93 143 0.65 180

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 30

0037_EN_2018_KERN[21841696]-e.indd 39 12/17/2018 3:31:12 PM