Page 35 - Icon Ridge Presents ATORN

P. 35

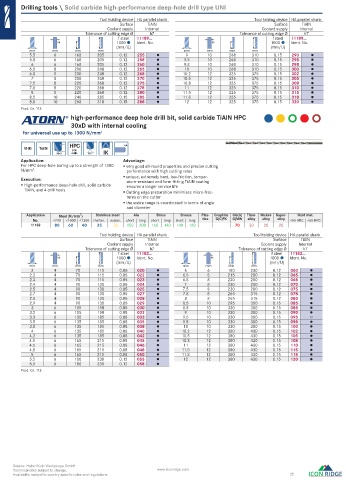

Drilling tools \ Solid carbide high-performance deep-hole drill type UNI

Tool holding device HA parallel shank Tool holding device HA parallel shank

Surface TiAlN Surface TiAlN

Coolant supply Internal Coolant supply Internal

Tolerance of cutting edge Ø h7 Tolerance of cutting edge Ø h7

f steel 11189... f steel 11189...

h6 1000 Ident. No. h6 1000 Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

5.5 6 168 205 0.12 255 9 10 268 310 0.15 290

5.8 6 168 205 0.12 258 9.5 10 268 310 0.15 295

6 6 168 205 0.12 260 9.8 10 268 310 0.15 298

6.5 8 200 240 0.12 265 10 10 268 310 0.15 300

6.8 8 200 240 0.12 268 10.2 12 325 375 0.15 302

7 8 200 240 0.12 270 10.5 12 325 375 0.15 305

7.5 8 220 260 0.12 275 10.8 12 325 375 0.15 308

7.8 8 220 260 0.12 278 11 12 325 375 0.15 310

8 8 220 260 0.12 280 11.5 12 325 375 0.15 315

8.5 10 240 285 0.15 285 11.8 12 325 375 0.15 318

8.8 10 268 310 0.15 288 12 12 325 375 0.15 320

Prod. Gr. 113

high-performance deep hole drill bit, solid carbide TiAlN HPC

30xD with internal cooling

for universal use up to 1300 N/mm 2

HPC HA

VHM TiAlN UNI

30xD 135° IK

Application: Advantage:

For HPC deep-hole boring up to a strength of 1300 very good all-round properties and precise cutting

N/mm . 2 performance with high cutting rates

Execution: unique, extremely hard, low-friction, temper-

ature-resistant and form-fi tting TiAlN coating

High-performance deep-hole drill, solid carbide ensures a longer service life

TiAlN, and 4 drill heels Cutting edge preparation minimises micro-frac-

tures on the cutter

the entire range is coordinated in terms of angle

and diameter

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11182 80 60 40 35 30 150 200 160 140 140 120 70 30 20 20

Tool holding device HA parallel shank Tool holding device HA parallel shank

Surface TiAlN Surface TiAlN

Coolant supply Internal Coolant supply Internal

Tolerance of cutting edge Ø h7 Tolerance of cutting edge Ø h7

f steel 11182... f steel 11182...

h6 1000 Ident. No. h6 1000 Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

2 4 70 115 0.05 020 6 6 180 230 0.12 060

2.2 4 70 115 0.05 022 6.5 8 215 280 0.12 065

2.3 4 70 115 0.05 023 6.8 8 230 280 0.12 068

2.4 4 90 138 0.05 024 7 8 230 280 0.12 070

2.5 4 90 138 0.05 025 7.5 8 230 280 0.12 075

2.7 4 90 138 0.05 027 7.8 8 265 315 0.12 078

2.8 4 90 138 0.05 028 8 8 265 315 0.12 080

2.9 4 90 138 0.05 029 8.5 10 295 350 0.15 085

3 6 105 150 0.05 030 8.8 10 330 380 0.15 088

3.2 6 105 150 0.08 032 9 10 330 380 0.15 090

3.3 6 135 185 0.08 033 9.5 10 330 380 0.15 095 ○

3.5 6 135 185 0.08 035 9.8 10 330 380 0.15 098

3.8 6 135 185 0.08 038 10 10 330 380 0.15 100

4 6 135 185 0.08 040 10.2 12 380 430 0.15 102

4.2 6 135 185 0.08 042 10.5 12 380 430 0.15 105

4.5 6 165 215 0.08 045 10.8 12 380 430 0.15 108

4.6 6 165 215 0.08 046 11 12 380 430 0.15 110

4.8 6 165 215 0.08 048 11.5 12 380 430 0.15 115

5 6 165 215 0.08 050 11.8 12 380 430 0.15 118

5.5 6 180 230 0.12 055 12 12 380 430 0.15 120

5.8 6 180 230 0.12 058

Prod. Gr. 113

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 35

0043_EN_2018_KERN[21841704]-k.indd 44 12/17/2018 3:30:59 PM