Page 31 - Icon Ridge Presents ATORN

P. 31

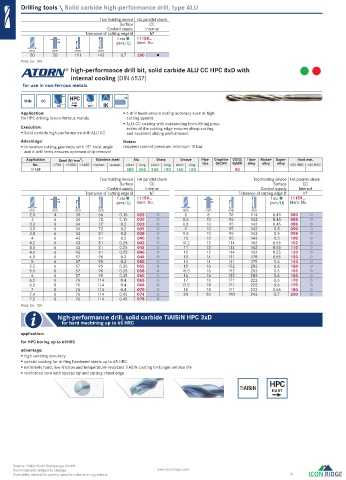

Drilling tools \ Solid carbide high-performance drill, type ALU

Tool holding device HA parallel shank

Surface CC

Coolant supply Internal

Tolerance of cutting edge Ø h7

f alu 11158...

h6 (mm/U) Ident. No.

mm mm mm mm

20 20 101 143 0.7 200

Prod. Gr. 134

high-performance drill bit, solid carbide ALU CC HPC 8xD with

internal cooling ( DIN 6537 )

for use in non-ferrous metals

HPC HA

VHM CC ALU

8xD 135° IK

Application: 6 drill heels ensure boring accuracy even at high

for HPC drilling in non-ferrous metals. cutting speeds

ALU-CC coating with outstanding form-fi tting prop-

Execution: erties of the cutting edge ensures sharp cutting

Solid carbide high-performance drill ALU CC and excellent sliding performance

Advantage: Notes:

innovative cutting geometry with 15° twist angle required coolant pressure: minimum 12 bar

and 6 drill heels ensures optimum chip removal

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11159 380 350 250 190 160 120 90

Tool holding device HA parallel shank Tool holding device HA parallel shank

Surface CC Surface CC

Coolant supply Internal Coolant supply Internal

Tolerance of cutting edge Ø h7 Tolerance of cutting edge Ø h7

f alu 11159... f alu 11159...

h6 (mm/U) Ident. No. h6 (mm/U) Ident. No.

mm mm mm mm mm mm mm mm

2.5 4 30 66 0.15 025 ○ 8 8 76 114 0.45 080 ○

3 6 34 72 0.15 030 ○ 8.5 10 95 142 0.45 085 ○

3.3 6 34 72 0.2 033 ○ 8.8 10 95 142 0.45 088 ○

3.5 6 34 72 0.2 035 ○ 9 10 95 142 0.5 090 ○

3.8 6 43 81 0.2 038 ○ 9.8 10 95 142 0.5 098 ○

4 6 43 81 0.2 040 ○ 10 10 95 142 0.5 100 ○

4.2 6 43 81 0.25 042 ○ 10.2 12 114 162 0.55 102 ○

4.5 6 43 81 0.25 045 ○ 11 12 114 162 0.55 110 ○

4.6 6 43 81 0.25 046 ○ 12 12 114 162 0.55 120 ○

4.8 6 57 95 0.3 048 ○ 13 14 131 178 0.55 130 ○

5 6 57 95 0.3 050 ○ 14 14 131 178 0.6 140 ○

5.5 6 57 95 0.35 055 ○ 15 16 152 203 0.6 150 ○

5.8 6 57 95 0.35 058 ○ 15.5 16 152 203 0.6 155 ○

6 6 57 95 0.35 060 ○ 16 16 152 203 0.6 160 ○

6.5 8 76 114 0.4 065 ○ 17 18 171 222 0.6 170 ○

6.8 8 76 114 0.4 068 ○ 17.5 18 171 222 0.6 175 ○

7 8 76 114 0.4 070 ○ 18 18 171 222 0.65 180 ○

7.4 8 76 114 0.45 074 ○ 20 20 190 243 0.7 200 ○

7.8 8 76 114 0.45 078 ○

Prod. Gr. 134

high-performance drill, solid carbide TiAISiN HPC 3xD

for hard machining up to 65 HRC

application:

for HPC boring up to 65HRC

advantage:

high centring accuracy

special coating for drilling hardened steels up to 65 HRC

extremely hard, low-friction and temperature-resistant TiASiN coating for longer service life

reinforced core with special tip and cutting chisel edge

HPC

TiAlSiN HART

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 31

0037_EN_2018_KERN[21841696]-e.indd 40 12/17/2018 3:31:16 PM