Page 36 - Icon Ridge Presents ATORN

P. 36

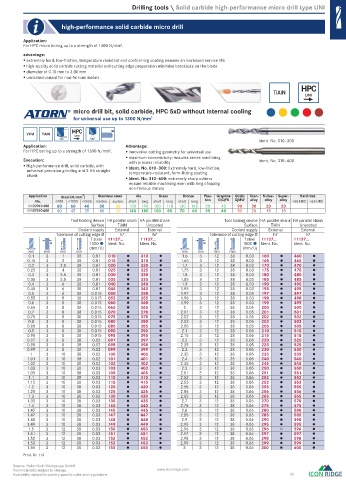

Drilling tools \ Solid carbide high-performance micro drill type UNI

high-performance solid carbide micro drill

Application:

For HPC micro boring up to a strength of 1300 N/mm . 2

advantage:

extremely hard, low-friction, temperature resistant and conforming coating ensures an increased service life

high-quality solid carbide cutting material and cutting edge preparation minimise breakouts on the blade

diameter of 0.10 mm to 3.00 mm

uncoated variant for non-ferrous metals

HPC

TiAlN

UNI

micro drill bit, solid carbide, HPC 5xD without internal cooling

for universal use up to 1300 N/mm 2

HPC HA

VHM TiAlN UNI

5xD 130° Ident. No. 010–300

Application: Advantage:

For HPC boring up to a strength of 1300 N/mm . 2 innovative cutting geometry for universal use

Execution: maximum concentricity: ensures series machining Ident. No. 310–600

with process reliability

High-performance drill, solid carbide, with Ident. No. 010–300: Extremely hard, low-friction,

universal precision grinding and 3 H6 straight temperature-resistant, form-fi tting coating

shank

Ident. No. 310–600: extremely sharp cutters

ensure reliable machining even with long chipping

non-ferrous metals

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11137010-300 60 60 40 30 30 150 190 100 110 130 140 50 40 90 30 20 20

11137310-600 60 45 35 40 30 140 180 100 80 70 60 55 40 50 20 15 15

Tool holding device HA parallel shank HA parallel shank Tool holding device HA parallel shank HA parallel shank

Surface TiAlN Uncoated Surface TiAlN Uncoated

Coolant supply External External Coolant supply External External

Tolerance of cutting edge Ø h7 h7 Tolerance of cutting edge Ø h7 h7

f steel 11137... 11137... f steel 11137... 11137...

h6 1000 Ident. No. Ident. No. h6 1000 Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

0.1 3 1 38 0.01 010 310 1.6 3 12 38 0.03 160 460

0.15 3 2 38 0.01 015 315 1.65 3 12 38 0.03 165 465

0.2 3 2.5 38 0.01 020 320 1.7 3 12 38 0.03 170 470

0.25 3 4 38 0.01 025 325 1.75 3 12 38 0.03 175 475

0.3 3 5.5 38 0.01 030 330 1.8 3 12 38 0.03 180 480

0.35 3 5.5 38 0.01 035 335 1.85 3 12 38 0.03 185 485

0.4 3 6 38 0.01 040 340 1.9 3 12 38 0.03 190 490

0.45 3 6 38 0.01 045 345 1.95 3 12 38 0.03 195 495

0.5 3 6 38 0.015 050 350 1.97 3 12 38 0.03 197 497

0.55 3 8 38 0.015 055 355 1.98 3 12 38 0.03 198 498

0.6 3 8 38 0.015 060 360 1.99 3 12 38 0.03 199 499

0.65 3 8 38 0.015 065 365 2 3 12 38 0.05 200 500

0.7 3 8 38 0.015 070 370 2.01 3 12 38 0.05 201 501

0.75 3 8 38 0.015 075 375 2.02 3 12 38 0.05 202 502

0.8 3 8 38 0.015 080 380 2.03 3 12 38 0.05 203 503

0.85 3 8 38 0.015 085 385 2.05 3 12 38 0.05 205 505

0.9 3 8 38 0.015 090 390 2.1 3 12 38 0.05 210 510

0.95 3 8 38 0.015 095 395 2.15 3 12 38 0.05 215 515

0.97 3 8 38 0.02 097 397 2.2 3 12 38 0.05 220 520

0.98 3 8 38 0.02 098 398 2.25 3 12 38 0.05 225 525

0.99 3 8 38 0.02 099 399 2.3 3 12 38 0.05 230 530

1 3 10 38 0.02 100 400 2.35 3 12 38 0.05 235 535

1.01 3 10 38 0.02 101 401 2.4 3 12 38 0.05 240 540

1.02 3 10 38 0.03 102 402 2.45 3 12 38 0.05 245 545

1.03 3 10 38 0.03 103 403 2.5 3 12 38 0.05 250 550

1.05 3 10 38 0.03 105 405 2.51 3 12 38 0.06 251 551

1.1 3 10 38 0.03 110 410 2.52 3 12 38 0.06 252 552

1.15 3 10 38 0.03 115 415 2.53 3 12 38 0.06 253 553

1.2 3 10 38 0.03 120 420 2.55 3 12 38 0.06 255 555

1.25 3 10 38 0.03 125 425 2.56 3 12 38 0.06 256 556

1.3 3 10 38 0.03 130 430 2.65 3 12 38 0.06 265 565

1.35 3 10 38 0.03 135 435 2.7 3 12 38 0.06 270 570

1.4 3 10 38 0.03 140 440 2.75 3 12 38 0.06 275 575

1.45 3 10 38 0.03 145 445 2.8 3 12 38 0.06 280 580

1.47 3 10 38 0.03 147 447 2.85 3 12 38 0.06 285 585

1.48 3 10 38 0.03 148 448 2.9 3 12 38 0.06 290 590

1.49 3 10 38 0.03 149 449 2.95 3 12 38 0.06 295 595

1.5 3 12 38 0.03 150 450 2.96 3 12 38 0.06 296 ○ 596

1.51 3 12 38 0.03 151 451 2.97 3 12 38 0.06 297 597

1.52 3 12 38 0.03 152 452 2.98 3 12 38 0.06 298 598

1.53 3 12 38 0.03 153 453 2.99 3 12 38 0.06 299 599

1.55 3 12 38 0.03 155 455 3 3 12 38 0.06 300 600

Prod. Gr. 113

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 36

0045_EN_2018_KERN[21841708]-m.indd 45 12/17/2018 3:31:01 PM