Page 335 - Icon Ridge Presents ATORN

P. 335

Milling tools monoblock \ Solid carbide mills for machining graphite

ULTRA DC coating – hard as a diamond

for machining graphite, carbon/fi breglass, we coat our torus and radius cutter with the special ULTRA DC

coating. thanks to the extremely adhesive CVD high-performance coating, the tools have similar physical and

chemical properties as natural diamond. extreme hardness and smoothness, high chemical resistance and

very good heat conductivity and abrasion resistance make them extremely powerful and stable. for a long

service life, the milling tools are equipped with a layer thickness of 10+2 m or 6+2 µm.

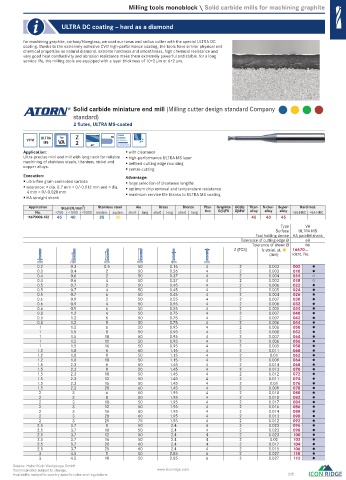

Solid carbide miniature end mill ( Milling cutter design standard Company

standard )

2 fl utes, ULTRA MS-coated

ULTRA Typ Z HA

VHM VA

MS 2

Application: with clearance

Ultra-precise mini end mill with long neck for reliable high-performance ULTRA MS layer

machining of stainless steels, titanium, nickel and defi ned cutting edge rounding

copper alloys. centre cutting

Execution: Advantage:

ultra-fi ne grain cemented carbide large selection of clearance lengths

tolerance: < dia. 0.7 mm = 0/-0.012 mm and < dia. optimum chip removal and temperature resistance

4 mm = 0/-0.020 mm maximum service life thanks to ULTRA MS coating

HA straight shank

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16670002-132 45 40 35 30 45 40 45

Type VA

Surface ULTRA MS

Tool holding device HA parallel shank

Tolerance of cutting edge Ø e8

Tolerance of shank Ø h6

Z (PCS) fz steinl. st. 16670...

(mm) Ident. No.

mm mm mm mm mm mm

0.2 0.3 0.5 50 0.16 4 2 0.003 002

0.3 0.4 2 50 0.26 4 2 0.003 010

0.4 0.6 2 50 0.37 4 2 0.004 014 ○

0.4 0.6 4 50 0.37 4 2 0.003 018 ○

0.5 0.7 2 50 0.45 4 2 0.006 022

0.5 0.7 4 50 0.45 4 2 0.005 024

0.5 0.7 6 50 0.45 4 2 0.004 026

0.6 0.9 2 50 0.55 4 2 0.007 030

0.6 0.9 4 50 0.55 4 2 0.006 032

0.6 0.9 6 50 0.55 4 2 0.005 034

0.8 1.2 4 50 0.75 4 2 0.007 040

0.8 1.2 6 50 0.75 4 2 0.007 042

0.8 1.2 8 50 0.75 4 2 0.006 044

1 1.5 6 50 0.95 4 2 0.008 050

1 1.5 8 50 0.95 4 2 0.008 052

1 1.5 10 50 0.95 4 2 0.007 054

1 1.5 12 50 0.95 4 2 0.006 056

1 1.5 16 50 0.95 4 2 0.005 058

1.2 1.8 6 50 1.15 4 2 0.011 060

1.2 1.8 8 50 1.15 4 2 0.01 062

1.2 1.8 10 50 1.15 4 2 0.009 064

1.5 2.3 6 50 1.45 4 2 0.014 068

1.5 2.3 8 50 1.45 4 2 0.013 070

1.5 2.3 10 50 1.45 4 2 0.012 072

1.5 2.3 12 50 1.45 4 2 0.011 074

1.5 2.3 16 50 1.45 4 2 0.01 076

1.5 2.3 20 60 1.45 4 2 0.009 078

2 3 6 50 1.95 4 2 0.018 080

2 3 8 50 1.95 4 2 0.018 082

2 3 10 50 1.95 4 2 0.017 084

2 3 12 50 1.95 4 2 0.016 086

2 3 16 50 1.95 4 2 0.014 088

2 3 20 60 1.95 4 2 0.013 090

2 3 25 75 1.95 4 2 0.012 092

2.5 3.7 8 50 2.4 4 2 0.023 096

2.5 3.7 10 50 2.4 4 2 0.023 098

2.5 3.7 12 50 2.4 4 2 0.023 100

2.5 3.7 16 50 2.4 4 2 0.02 102

2.5 3.7 20 60 2.4 4 2 0.017 104

2.5 3.7 25 60 2.4 4 2 0.015 106

3 4.5 8 50 2.85 6 2 0.027 110

3 4.5 10 50 2.85 6 2 0.027 112

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 335

0404_EN_2018_KERN[21847657]-k.indd 405 12/17/2018 3:32:35 PM