Page 337 - Icon Ridge Presents ATORN

P. 337

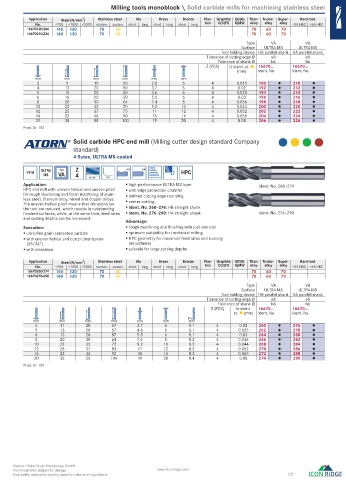

Milling tools monoblock \ Solid carbide mills for machining stainless steel

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16670190-206 140 130 70 60 70 60 70

16670210-226 140 130 70 60 70 60 70

Type VA VA

Surface ULTRA MS ULTRA MS

Tool holding device HB parallel shank HA parallel shank

Tolerance of cutting edge Ø e8 e8

Tolerance of shank Ø h6 h6

Z (PCS) fz steinl. st. 16670... 16670...

(mm) Ident. No. Ident. No.

mm mm mm mm mm mm

3 9 15 50 2.8 6 4 0.015 190 210

4 12 20 50 3.7 6 4 0.02 192 212

5 15 20 50 4.6 6 4 0.025 194 214

6 16 20 50 5.5 6 4 0.03 196 216

8 20 30 64 7.4 8 4 0.036 198 218

10 22 32 70 9.2 10 4 0.044 200 220

12 25 37 75 11 12 4 0.052 202 222

16 32 46 90 15 16 4 0.065 204 224

20 38 58 100 19 20 4 0.08 206 226

Prod. Gr. 152

Solid carbide HPC end mill ( Milling cutter design standard Company

standard )

4 fl utes, ULTRA MS-coated

VHM ULTRA Typ Z HB HA HPC

MS VA 4 35°/38° 45°

Application: high-performance ULTRA MS layer Ident. No. 260–274

HPC end mill with uneven helical and uneven pitch with edge protection chamfer

for rough machining and fi nish machining of stain- defi ned cutting edge rounding

less steel, titanium alloy, nickel and copper alloys. centre cutting

The uneven helical pitch means that vibrations on

the tool are reduced, which results in outstanding Ident. No. 260–274: HB straight shank

fi nished surfaces, while, at the same time, feed rates Ident. No. 276–290: HA straight shank Ident. No. 276–290

and cutting depths can be increased. Advantage:

Execution: rough machining and fi nishing with just one tool

ultra-fi ne grain cemented carbide optimum suitability for trochoidal milling

with uneven helical and cutter distribution HPC geometry for maximum feed rates and running

(35/38°) smoothness

with clearance suitable for large cutting depths

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16670260-274 140 130 70 60 70 60 70

16670276-290 140 130 70 60 70 60 70

Type VA VA

Surface ULTRA MS ULTRA MS

Tool holding device HB parallel shank HA parallel shank

Tolerance of cutting edge Ø e8 e8

Tolerance of shank Ø h6 h6

Z (PCS) fz steinl. 16670... 16670...

st. (mm) Ident. No. Ident. No.

mm mm mm mm mm mm mm

4 11 20 57 3.7 6 0.1 4 0.02 260 276

5 13 20 57 4.6 6 0.1 4 0.025 262 278

6 13 20 57 5.5 6 0.1 4 0.03 264 280

8 20 30 64 7.4 8 0.2 4 0.036 266 282

10 22 32 72 9.2 10 0.2 4 0.044 268 284

12 26 37 83 11 12 0.2 4 0.052 270 286

16 32 46 92 15 16 0.3 4 0.065 272 288

20 38 58 104 19 20 0.4 4 0.08 274 290

Prod. Gr. 152

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 337

0404_EN_2018_KERN[21847657]-k.indd 407 12/17/2018 3:32:40 PM