Page 341 - Icon Ridge Presents ATORN

P. 341

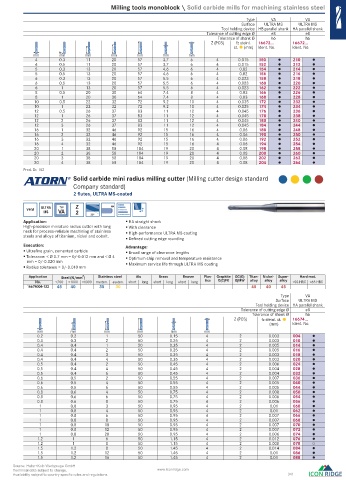

Milling tools monoblock \ Solid carbide mills for machining stainless steel

Type VA VA

Surface ULTRA MS ULTRA MS

Tool holding device HB parallel shank HA parallel shank

Tolerance of cutting edge Ø e8 e8

Tolerance of shank Ø h6 h6

Z (PCS) fz steinl. 16672... 16672...

st. (mm) Ident. No. Ident. No.

mm mm mm mm mm mm mm

4 0.3 11 20 57 3.7 6 4 0.015 150 210

4 0.5 11 20 57 3.7 6 4 0.015 152 212

5 0.3 13 20 57 4.6 6 4 0.02 154 214

5 0.5 13 20 57 4.6 6 4 0.02 156 216

6 0.3 13 20 57 5.5 6 4 0.023 158 218

6 0.5 13 20 57 5.5 6 4 0.023 160 220

6 1 13 20 57 5.5 6 4 0.023 162 222

8 0.5 20 30 64 7.4 8 4 0.03 166 226

8 1 20 30 64 7.4 8 4 0.03 168 228

10 0.5 22 32 72 9.2 10 4 0.035 172 232

10 1 22 32 72 9.2 10 4 0.035 174 234

12 0.5 26 37 83 11 12 4 0.045 176 236

12 1 26 37 83 11 12 4 0.045 178 238

12 2 26 37 83 11 12 4 0.045 180 240

12 3 26 37 83 11 12 4 0.045 184 244

16 1 32 46 92 15 16 4 0.06 188 248

16 2 32 46 92 15 16 4 0.06 190 250

16 3 32 46 92 15 16 4 0.06 192 252

16 4 32 46 92 15 16 4 0.06 194 254

20 1 38 58 104 19 20 4 0.08 198 258

20 2 38 58 104 19 20 4 0.08 200 260

20 3 38 58 104 19 20 4 0.08 202 262

20 4 38 58 104 19 20 4 0.08 204 264

Prod. Gr. 152

Solid carbide mini radius milling cutter ( Milling cutter design standard

Company standard )

2 fl utes, ULTRA MS-coated

ULTRA Typ Z HA

VHM VA

MS 2

Application: HA straight shank

High-precision miniature radius cutter with long With clearance

neck for process-reliable machining of stainless High-performance ULTRA MS coating

steels and alloys of titanium, nickel and cobalt. Defi ned cutting edge rounding

Execution: Advantage:

Ultrafi ne grain, cemented carbide Broad range of clearance lengths

Tolerance: < Ø 0.7 mm = 0/-0.012 mm and < Ø 4 Optimum chip removal and temperature resistance

mm = 0/-0.020 mm Maximum service life through ULTRA MS coating

Radius tolerance = 0/-0.010 mm

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16674004-132 45 40 35 30 45 40 45

Type VA

Surface ULTRA MS

Tool holding device HA parallel shank

Tolerance of cutting edge Ø e8

Tolerance of shank Ø h6

Z (PCS) fz steinl. st. 16674...

(mm) Ident. No.

mm mm mm mm mm mm

0.2 0.2 1 50 0.15 4 2 0.003 004

0.3 0.3 2 50 0.25 4 2 0.003 010

0.4 0.4 1 50 0.35 4 2 0.005 014

0.4 0.4 2 50 0.35 4 2 0.005 016

0.4 0.4 3 50 0.35 4 2 0.003 018

0.4 0.4 4 50 0.35 4 2 0.003 020

0.5 0.4 2 50 0.45 4 2 0.006 024

0.5 0.4 4 50 0.45 4 2 0.004 028

0.5 0.4 6 50 0.45 4 2 0.004 032

0.6 0.5 2 50 0.55 4 2 0.007 036

0.6 0.5 4 50 0.55 4 2 0.005 040

0.6 0.5 6 50 0.55 4 2 0.005 044

0.8 0.6 4 50 0.75 4 2 0.008 050

0.8 0.6 6 50 0.75 4 2 0.006 054

0.8 0.6 8 50 0.75 4 2 0.006 056

1 0.8 3 50 0.95 4 2 0.01 060

1 0.8 4 50 0.95 4 2 0.01 062

1 0.8 6 50 0.95 4 2 0.007 066

1 0.8 8 50 0.95 4 2 0.007 068

1 0.8 10 50 0.95 4 2 0.007 070

1 0.8 12 50 0.95 4 2 0.007 072

1 0.8 20 50 0.95 4 2 0.006 074

1.2 1 6 50 1.15 4 2 0.012 076

1.2 1 8 50 1.15 4 2 0.008 078 ○

1.5 1.2 8 50 1.45 4 2 0.014 084

1.5 1.2 12 50 1.45 4 2 0.01 086

1.5 1.2 16 50 1.45 4 2 0.01 088

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 341

0408_EN_2018_KERN[21847665]-m.indd 411 12/17/2018 3:32:40 PM