Page 340 - Icon Ridge Presents ATORN

P. 340

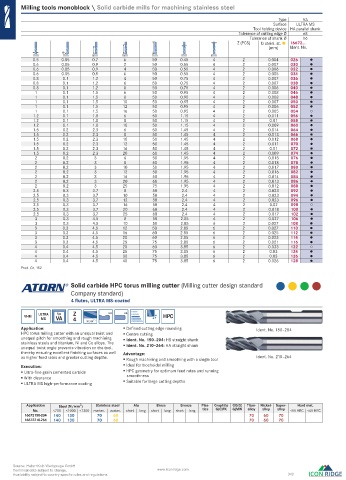

Milling tools monoblock \ Solid carbide mills for machining stainless steel

Type VA

Surface ULTRA MS

Tool holding device HA parallel shank

Tolerance of cutting edge Ø e8

Tolerance of shank Ø h6

Z (PCS) fz steinl. st. 16672...

(mm) Ident. No.

mm mm mm mm mm mm mm

0.5 0.05 0.7 6 50 0.45 4 2 0.004 026

0.6 0.05 0.9 2 50 0.55 4 2 0.007 030

0.6 0.05 0.9 4 50 0.55 4 2 0.006 032

0.6 0.05 0.9 6 50 0.55 4 2 0.005 034

0.8 0.1 1.2 4 50 0.75 4 2 0.007 036

0.8 0.1 1.2 6 50 0.75 4 2 0.007 038

0.8 0.1 1.2 8 50 0.75 4 2 0.006 040

1 0.1 1.5 6 50 0.95 4 2 0.008 046

1 0.1 1.5 8 50 0.95 4 2 0.008 048

1 0.1 1.5 10 50 0.95 4 2 0.007 050

1 0.1 1.5 12 50 0.95 4 2 0.006 052

1 0.1 1.5 16 50 0.95 4 2 0.005 054 ○

1.2 0.1 1.8 6 50 1.15 4 2 0.011 056

1.2 0.1 1.8 8 50 1.15 4 2 0.01 058

1.2 0.1 1.8 10 50 1.15 4 2 0.009 060

1.5 0.2 2.3 6 50 1.45 4 2 0.014 064

1.5 0.2 2.3 8 50 1.45 4 2 0.013 066

1.5 0.2 2.3 10 50 1.45 4 2 0.012 068

1.5 0.2 2.3 12 50 1.45 4 2 0.011 070

1.5 0.2 2.3 16 50 1.45 4 2 0.01 072

1.5 0.2 2.3 20 60 1.45 4 2 0.009 074

2 0.2 3 6 50 1.95 4 2 0.018 076

2 0.2 3 8 50 1.95 4 2 0.018 078

2 0.2 3 10 50 1.95 4 2 0.017 080

2 0.2 3 12 50 1.95 4 2 0.016 082

2 0.2 3 16 50 1.95 4 2 0.014 084

2 0.2 3 20 60 1.95 4 2 0.013 086

2 0.2 3 25 75 1.95 4 2 0.012 088

2.5 0.3 3.7 8 50 2.4 4 2 0.023 092

2.5 0.3 3.7 10 50 2.4 4 2 0.023 094

2.5 0.3 3.7 12 50 2.4 4 2 0.023 096

2.5 0.3 3.7 16 50 2.4 4 2 0.02 098 ○

2.5 0.3 3.7 20 60 2.4 4 2 0.018 100

2.5 0.3 3.7 25 60 2.4 4 2 0.017 102

3 0.3 4.5 8 50 2.85 6 2 0.027 106

3 0.3 4.5 10 50 2.85 6 2 0.027 108

3 0.3 4.5 12 50 2.85 6 2 0.027 110

3 0.3 4.5 16 60 2.85 6 2 0.025 112

3 0.3 4.5 20 60 2.85 6 2 0.023 114

3 0.3 4.5 25 75 2.85 6 2 0.021 116

4 0.4 4.5 20 60 3.85 6 2 0.033 122 ○

4 0.4 4.5 25 75 3.85 6 2 0.03 124

4 0.4 4.5 30 75 3.85 6 2 0.03 126

4 0.4 4.5 40 75 3.85 6 2 0.026 128

Prod. Gr. 152

Solid carbide HPC torus milling cutter ( Milling cutter design standard

Company standard )

4 fl utes, ULTRA MS-coated

VHM ULTRA Typ Z HB HA HPC

MS VA 4 35°/38°

Application: Defi ned cutting edge rounding Ident. No. 150–204

HPC torus milling cutter with an unequal twist and Centre cutting

unequal pitch for smoothing and rough machining Ident. No. 150–204: HB straight shank

stainless steels and titanium, Ni and Co alloys. The Ident. No. 210–264: HA straight shank

unequal twist angle prevents vibration on the tool,

thereby ensuring excellent fi nishing surfaces as well Advantage:

as higher feed rates and greater cutting depths. Rough machining and smoothing with a single tool Ident. No. 210–264

Execution: Ideal for trochoidal milling

Ultra-fi ne grain cemented carbide HPC geometry for optimum feed rates and running

With clearance smoothness

ULTRA MS high-performance coating Suitable for large cutting depths

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16672150-204 140 130 70 60 70 60 70

16672210-264 140 130 70 60 70 60 70

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 340

0408_EN_2018_KERN[21847665]-m.indd 410 12/17/2018 3:32:39 PM