Page 494 - Icon Ridge Presents ATORN

P. 494

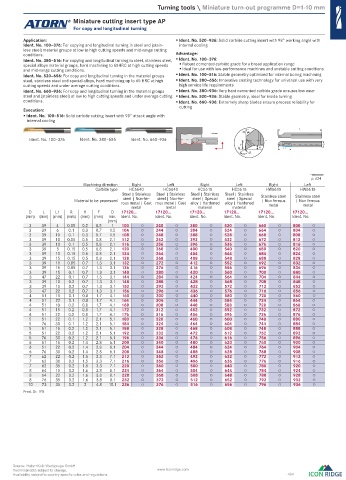

Turning tools \ Miniature turn-out programme D=1-10 mm

Miniature cutting insert type AP

For copy and longitudinal turning

Application: Ident. No. 520–936: Solid carbide cutting insert with 98° working angle with

Ident. No. 100–376: For copying and longitudinal turning in steel and (stain- internal cooling

less steel) material groups at low to high cutting speeds and mid-range cutting

conditions. Advantage:

Ident. No. 380–516: For copying and longitudinal turning in steel, stainless steel, Ident. No. 100–376:

special alloys material groups, hard machining to 65HRC at high cutting speeds Robust cemented carbide grade for a broad application range

and mid-range cutting conditions. Ideal for use with low-performance machines and unstable cutting conditions

Ident. No. 520–656: For copy and longitudinal turning in the material groups Ident. No. 100–516: Stable geometry optimised for internal boring machining

steel, stainless steel and special alloys, hard machining up to 65 HRC at high Ident. No. 380–656: Innovative coating technology for universal use with very

cutting speeds and under average cutting conditions. high service life requirements

Ident. No. 660–936: For copy and longitudinal turning in the material groups Ident. No. 380–936: Very hard cemented carbide grade ensures low wear

steel and (stainless steel) at low to high cutting speeds and under average cutting Ident. No. 520–936: Stable geometry, ideal for inside turning

conditions. Ident. No. 660–936: Extremely sharp blades ensure process reliability for

Execution: cutting

Ident. No. 100–516: Solid carbide cutting insert with 98° attack angle with

internal cooling

8° L

> 1mm

Ident. No. 100–376 Ident. No. 380–656 Ident. No. 660–936

F D

H L1

R

22°

p. 624

Machining direction Right Le Right Le Right Le

Carbide type HC5640 HC5640 HC5615 HC5615 HW5615 HW5615

Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Stainless steel Stainless steel

steel | Special

steel | Special

steel | Non-fer-

steel | Non-fer-

Material to be processed rous metal | Cast rous metal | Cast alloy | Hardened alloy | Hardened | Non-ferrous | Non-ferrous

metal metal material material metal metal

D L L1 R H F D 17120... 17120... 17120... 17120... 17120... 17120...

(mm) (mm) (mm) (mm) (mm) (mm) min. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

(mm)

3 39 4 0.05 0.2 0.5 1 100 ○ 240 ○ 380 ○ 520 ○ 660 ○ 800 ○

3 39 6 0.1 0.3 0.7 1.5 104 ○ 244 ○ 384 ○ 524 ○ 664 ○ 804 ○

3 39 10 0.1 0.3 0.7 1.5 108 ○ 248 ○ 388 ○ 528 ○ 668 ○ 808 ○

3 39 10 0.05 0.5 0.8 2.1 112 ○ 252 ○ 392 ○ 532 ○ 672 ○ 812 ○

3 39 10 0.1 0.5 0.8 2.1 116 ○ 256 ○ 396 ○ 536 ○ 676 ○ 816 ○

3 39 5 0.15 0.5 0.8 2.1 120 ○ 260 ○ 400 ○ 540 ○ 680 ○ 820 ○

3 39 10 0.15 0.5 0.8 2.1 124 ○ 264 ○ 404 ○ 544 ○ 684 ○ 824 ○

3 39 15 0.15 0.5 0.8 2.1 128 ○ 268 ○ 408 ○ 548 ○ 688 ○ 828 ○

3 39 10 0.05 0.7 1.3 3.1 132 ○ 272 ○ 412 ○ 552 ○ 692 ○ 832 ○

3 39 15 0.05 0.7 1.3 3.1 136 ○ 276 ○ 416 ○ 556 ○ 696 ○ 836 ○

3 39 15 0.1 0.7 1.3 3.1 140 ○ 280 ○ 420 ○ 560 ○ 700 ○ 840 ○

3 47 22 0.1 0.7 1.3 3.1 144 ○ 284 ○ 424 ○ 564 ○ 704 ○ 844 ○

3 39 10 0.2 0.7 1.3 3.1 148 ○ 288 ○ 428 ○ 568 ○ 708 ○ 848 ○

3 39 15 0.2 0.7 1.3 3.1 152 ○ 292 ○ 432 ○ 572 ○ 712 ○ 852 ○

3 47 22 0.2 0.7 1.3 3.1 156 ○ 296 ○ 436 ○ 576 ○ 716 ○ 856 ○

4 51 15 0.1 0.8 1.7 4.1 160 ○ 300 ○ 440 ○ 580 ○ 720 ○ 860 ○

4 51 22 0.1 0.8 1.7 4.1 164 ○ 304 ○ 444 ○ 584 ○ 724 ○ 864 ○

4 51 10 0.2 0.8 1.7 4.1 168 ○ 308 ○ 448 ○ 588 ○ 728 ○ 868 ○

4 51 15 0.2 0.8 1.7 4.1 172 ○ 312 ○ 452 ○ 592 ○ 732 ○ 872 ○

4 51 22 0.2 0.8 1.7 4.1 176 ○ 316 ○ 456 ○ 596 ○ 736 ○ 876 ○

5 51 22 0.1 1.2 2.1 5.1 180 ○ 320 ○ 460 ○ 600 ○ 740 ○ 880 ○

5 76 30 0.1 1.2 2.1 5.1 184 ○ 324 ○ 464 ○ 604 ○ 744 ○ 884 ○

5 51 15 0.2 1.2 2.1 5.1 188 ○ 328 ○ 468 ○ 608 ○ 748 ○ 888 ○

5 51 22 0.2 1.2 2.1 5.1 192 ○ 332 ○ 472 ○ 612 ○ 752 ○ 892 ○

5 76 30 0.2 1.2 2.1 5.1 196 ○ 336 ○ 476 ○ 616 ○ 756 ○ 896 ○

6 51 15 0.2 1.4 2.8 6.1 200 ○ 340 ○ 480 ○ 620 ○ 760 ○ 900 ○

6 51 22 0.2 1.4 2.8 6.1 204 ○ 344 ○ 484 ○ 624 ○ 764 ○ 904 ○

6 76 30 0.2 1.4 2.8 6.1 208 ○ 348 ○ 488 ○ 628 ○ 768 ○ 908 ○

7 62 22 0.2 1.5 3.3 7.1 212 ○ 352 ○ 492 ○ 632 ○ 772 ○ 912 ○

7 62 30 0.2 1.5 3.3 7.1 216 ○ 356 ○ 496 ○ 636 ○ 776 ○ 916 ○

7 62 35 0.2 1.5 3.3 7.1 220 ○ 360 ○ 500 ○ 640 ○ 780 ○ 920 ○

8 64 15 0.2 1.6 3.8 8.1 224 ○ 364 ○ 504 ○ 644 ○ 784 ○ 924 ○

8 64 22 0.2 1.6 3.8 8.1 228 ○ 368 ○ 508 ○ 648 ○ 788 ○ 928 ○

8 76 35 0.2 1.6 3.8 8.1 232 ○ 372 ○ 512 ○ 652 ○ 792 ○ 932 ○

10 73 35 0.2 2 4.8 10.1 236 ○ 376 ○ 516 ○ 656 ○ 796 ○ 936 ○

Prod. Gr. 1FB

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 494

0626_EN_2018_KERN[21847949]-g.indd 627 12/17/2018 3:33:12 PM