Page 496 - Icon Ridge Presents ATORN

P. 496

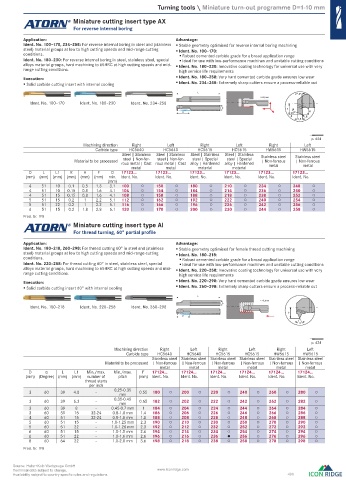

Turning tools \ Miniature turn-out programme D=1-10 mm

Miniature cutting insert type AX

For reverse internal boring

Application: Advantage:

Ident. No. 100–170, 234–258: For reverse internal boring in steel and (stainless Stable geometry optimised for reverse internal boring machining

steel) material groups at low to high cutting speeds and mid-range cutting Ident. No. 100–170:

conditions. Robust cemented carbide grade for a broad application range

Ident. No. 180–230: For reverse internal boring in steel, stainless steel, special Ideal for use with low-performance machines and unstable cutting conditions

alloys material groups, hard machining to 65HRC at high cutting speeds and mid- Ident. No. 180–230: Innovative coating technology for universal use with very

range cutting conditions. high service life requirements

Execution: Ident. No. 180–258: Very hard cemented carbide grade ensures low wear

Solid carbide cutting insert with internal cooling Ident. No. 234–258: Extremely sharp cutters ensure a process-reliable cut

L

2°

> 3,1mm

Ident. No. 100–170 Ident. No. 180–230 Ident. No. 234–258

D F

L1 30° H

R

1,5

p. 624

Machining direction Right Le Right Le Right Le

Carbide type HC5640 HC5640 HC5615 HC5615 HW5615 HW5615

Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Stainless steel Stainless steel

steel | Non-fer-

steel | Special

steel | Non-fer-

steel | Special

Material to be processed rous metal | Cast rous metal | Cast alloy | Hardened alloy | Hardened | Non-ferrous | Non-ferrous

metal metal material material metal metal

D L L1 R H F D 17123... 17123... 17123... 17123... 17123... 17123...

(mm) (mm) (mm) (mm) (mm) (mm) min. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

(mm)

4 51 10 0.1 0.5 1.3 3.1 100 ○ 150 ○ 180 ○ 210 ○ 234 ○ 248 ○

4 51 10 0.15 0.8 1.6 4.1 104 ○ 154 ○ 184 ○ 214 ○ 236 ○ 250 ○

4 51 15 0.15 0.8 1.6 4.1 108 ○ 158 ○ 188 ○ 218 ○ 238 ○ 252 ○

5 51 15 0.2 1 2.2 5.1 112 ○ 162 ○ 192 ○ 222 ○ 240 ○ 254 ○

5 51 22 0.2 1 2.2 5.1 116 ○ 166 ○ 196 ○ 226 ○ 242 ○ 256 ○

6 51 15 0.2 1.8 2.8 6.1 120 ○ 170 ○ 200 ○ 230 ○ 244 ○ 258 ○

Prod. Gr. 1FB

Miniature cutting insert type AI

For thread turning, 60° partial profi le

Application: Advantage:

Ident. No. 180–218, 260–298: For thread cutting 60° in steel and (stainless Stable geometry optimised for female thread cutting machining

steel) material groups at low to high cutting speeds and mid-range cutting Ident. No. 180–218:

conditions. Robust cemented carbide grade for a broad application range

Ident. No. 220–258: For thread cutting 60° in steel, stainless steel, special Ideal for use with low-performance machines and unstable cutting conditions

alloys material groups, hard machining to 65HRC at high cutting speeds and mid- Ident. No. 220–258: Innovative coating technology for universal use with very

range cutting conditions. high service life requirements

Execution: Ident. No. 220–298: Very hard cemented carbide grade ensures low wear

Solid carbide cutting insert 60° with internal cooling Ident. No. 260–298: Extremely sharp cutters ensure a process-reliable cut

L

> 3,2mm

D

Ident. No. 180–218 Ident. No. 220–258 Ident. No. 260–298

F

L1

p. 624

Machining direction Right Le Right Le Right Le

Carbide type HC5640 HC5640 HC5615 HC5615 HW5615 HW5615

Stainless steel Stainless steel Stainless steel Stainless steel Stainless steel Stainless steel

Material to be processed | Non-ferrous | Non-ferrous | Non-ferrous | Non-ferrous | Non-ferrous | Non-ferrous

metal metal metal metal metal metal

D α L L1 Min./max. Min./max. F 17124... 17124... 17124... 17124... 17124... 17124...

(mm) (Degree) (mm) (mm) number of pitch (mm) Ident. No. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

thread starts

per inch

3 60 39 4.8 - 0.25-0.35 0.55 180 ○ 200 ○ 220 ○ 240 ○ 260 ○ 280 ○

mm

3 60 39 6.3 - 0.35-0.45 0.65 182 ○ 202 ○ 222 ○ 242 ○ 262 ○ 282 ○

mm

3 60 39 8 - 0.45-0.7 mm 1 184 ○ 204 ○ 224 ○ 244 ○ 264 ○ 284 ○

3 60 39 15 32-24 0.8-1.0 mm 1.4 186 ○ 206 ○ 226 ○ 246 ○ 266 ○ 286 ○

4 60 51 15 32-24 0.8-1.0 mm 1.8 188 ○ 208 ○ 228 ○ 248 ○ 268 ○ 288 ○

5 60 51 15 - 1.0-1.25 mm 2.3 190 ○ 210 ○ 230 ○ 250 ○ 270 ○ 290 ○

5 60 51 22 - 1.0-1.26 mm 2.3 192 ○ 212 ○ 232 ○ 252 ○ 272 ○ 292 ○

6 60 51 15 - 1.0-1.5 mm 2.6 194 ○ 214 ○ 234 ○ 254 ○ 274 ○ 294 ○

6 60 51 22 - 1.0-1.6 mm 2.6 196 ○ 216 ○ 236 256 ○ 276 ○ 296 ○

8 60 64 22 - 1.0-2.0 mm 3.6 198 ○ 218 ○ 238 ○ 258 ○ 278 ○ 298 ○

Prod. Gr. 1FB

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 496

0628_EN_2018_KERN[21847952]-m.indd 629 12/17/2018 3:33:13 PM