Page 495 - Icon Ridge Presents ATORN

P. 495

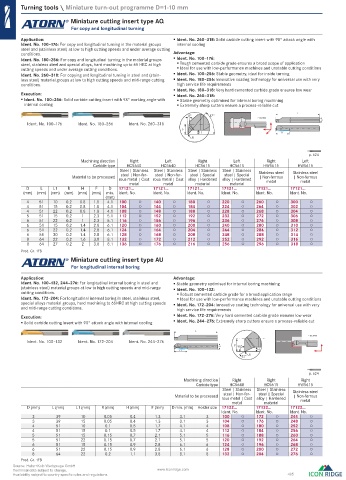

Turning tools \ Miniature turn-out programme D=1-10 mm

Miniature cutting insert type AQ

For copy and longitudinal turning

Application: Ident. No. 260–318: Solid carbide cutting insert with 98° attack angle with

Ident. No. 100–176: For copy and longitudinal turning in the material groups internal cooling

steel and (stainless steel) at low to high cutting speeds and under average cutting

conditions. Advantage:

Ident. No. 180–256: For copy and longitudinal turning in the material groups Ident. No. 100–176:

steel, stainless steel and special alloys, hard machining up to 65 HRC at high Tough cemented carbide grade ensures a broad scope of application

cutting speeds and under average cutting conditions. Ideal for use with low-performance machines and unstable cutting conditions

Ident. No. 260–318: For copying and longitudinal turning in steel and (stain- Ident. No. 100–256: Stable geometry, ideal for inside turning

less steel) material groups at low to high cutting speeds and mid-range cutting Ident. No. 180–256: Innovative coating technology for universal use with very

conditions. high service life requirements

Ident. No. 180–318: Very hard cemented carbide grade ensures low wear

Execution: Ident. No. 260–318:

Ident. No. 100–256: Solid carbide cutting insert with 98° working angle with Stable geometry optimised for internal boring machining

internal cooling Extremely sharp cutters ensure a process-reliable cut

L

8° 47°

> 4,1mm

D

Ident. No. 100–176 Ident. No. 180–256 Ident. No. 260–318

F

H L1

R

p. 624

Machining direction Right Le Right Le Right Le

Carbide type HC5640 HC5640 HC5615 HC5615 HW5615 HW5615

Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Stainless steel Stainless steel

steel | Special

steel | Special

steel | Non-fer-

steel | Non-fer-

Material to be processed rous metal | Cast rous metal | Cast alloy | Hardened alloy | Hardened | Non-ferrous | Non-ferrous

metal metal material material metal metal

D L L1 R H F D 17121... 17121... 17121... 17121... 17121... 17121...

(mm) (mm) (mm) (mm) (mm) (mm) min. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

(mm)

4 51 10 0.2 0.8 1.8 4.1 100 ○ 140 ○ 180 ○ 220 ○ 260 ○ 300 ○

4 51 15 0.2 0.8 1.8 4.1 104 ○ 144 ○ 184 ○ 224 ○ 264 ○ 302 ○

4 51 22 0.2 0.8 1.8 4.1 108 ○ 148 ○ 188 ○ 228 ○ 268 ○ 304 ○

5 51 15 0.2 1 2.3 5.1 112 ○ 152 ○ 192 ○ 232 ○ 272 ○ 306 ○

5 51 22 0.2 1 2.3 5.1 116 ○ 156 ○ 196 ○ 236 ○ 276 ○ 308 ○

6 51 15 0.2 1.4 2.8 6.1 120 ○ 160 ○ 200 ○ 240 ○ 280 ○ 310 ○

6 51 22 0.2 1.4 2.8 6.1 124 ○ 164 ○ 204 ○ 244 ○ 284 ○ 312 ○

6 58 30 0.2 1.4 2.8 6.1 128 ○ 168 ○ 208 ○ 248 ○ 288 ○ 314 ○

8 64 22 0.2 1.6 3.8 8.1 132 ○ 172 ○ 212 ○ 252 ○ 292 ○ 316 ○

8 64 27 0.2 2 3.8 8.1 136 ○ 176 ○ 216 ○ 256 ○ 296 ○ 318 ○

Prod. Gr. 1FB

Miniature cutting insert type AU

For longitudinal internal boring

Application: Advantage:

Ident. No. 100–132, 244–276: For longitudinal internal boring in steel and Stable geometry optimised for internal boring machining

(stainless steel) material groups at low to high cutting speeds and mid-range Ident. No. 100–132:

cutting conditions. Robust cemented carbide grade for a broad application range

Ident. No. 172–204: For longitudinal internal boring in steel, stainless steel, Ideal for use with low-performance machines and unstable cutting conditions

special alloys material groups, hard machining to 65HRC at high cutting speeds Ident. No. 172–204: Innovative coating technology for universal use with very

and mid-range cutting conditions. high service life requirements

Execution: Ident. No. 172–276: Very hard cemented carbide grade ensures low wear

Solid carbide cutting insert with 90° attack angle with internal cooling Ident. No. 244–276: Extremely sharp cutters ensure a process-reliable cut

L

> 3,1mm

Ident. No. 100–132 Ident. No. 172–204 Ident. No. 244–276

D F 90°

L1 H

22° R

p. 624

Machining direction Right Right Right

Carbide type HC5640 HC5615 HW5615

Steel | Stainless Steel | Stainless Stainless steel

steel | Special

steel | Non-fer-

Material to be processed rous metal | Cast alloy | Hardened | Non-ferrous

metal material metal

D (mm) L (mm) L1 (mm) R (mm) H (mm) F (mm) D min. (mm) Holder size 17122... 17122... 17122...

Ident. No. Ident. No. Ident. No.

3 39 10 0.05 0.4 1.3 3.1 3 100 ○ 172 ○ 244 ○

3 39 15 0.05 0.4 1.3 3.1 3 104 ○ 176 ○ 248 ○

4 51 10 0.1 0.5 1.7 4.1 4 108 ○ 180 ○ 252 ○

4 51 15 0.1 0.5 1.7 4.1 4 112 ○ 184 ○ 256 ○

5 51 15 0.15 0.7 2.1 5.1 5 116 ○ 188 ○ 260 ○

5 51 22 0.15 0.7 2.1 5.1 5 120 ○ 192 ○ 264 ○

6 51 15 0.15 0.9 2.8 6.1 6 124 ○ 196 ○ 268 ○

6 51 22 0.15 0.9 2.8 6.1 6 128 ○ 200 ○ 272 ○

8 64 22 0.2 1.1 3.8 8.1 8 132 ○ 204 ○ 276 ○

Prod. Gr. 1FB

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 495

0628_EN_2018_KERN[21847952]-m.indd 628 12/17/2018 3:33:10 PM