Page 498 - Icon Ridge Presents ATORN

P. 498

Turning tools \ Miniature turn-out programme D=1-10 mm

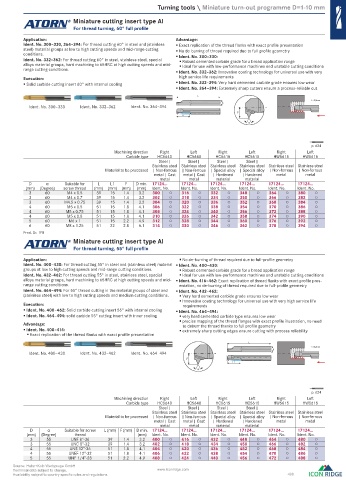

Miniature cutting insert type AI

For thread turning, 60° full profi le

Application: Advantage:

Ident. No. 300–330, 364–394: For thread cutting 60° in steel and (stainless Exact replication of the thread fl anks with exact profi le presentation

steel) material groups at low to high cutting speeds and mid-range cutting No de-burring of thread required due to full-profi le geometry

conditions. Ident. No. 300–330:

Ident. No. 332–362: For thread cutting 60° in steel, stainless steel, special Robust cemented carbide grade for a broad application range

alloys material groups, hard machining to 65HRC at high cutting speeds and mid- Ideal for use with low-performance machines and unstable cutting conditions

range cutting conditions.

Ident. No. 332–362: Innovative coating technology for universal use with very

Execution: high service life requirements

Solid carbide cutting insert 60° with internal cooling Ident. No. 332–394: Very hard cemented carbide grade ensures low wear

Ident. No. 364–394: Extremely sharp cutters ensure a process-reliable cut

L

> 3,2mm

D

Ident. No. 300–330 Ident. No. 332–362 Ident. No. 364–394

F

L1

p. 624

Machining direction Right Le Right Le Right Le

Carbide type HC5640 HC5640 HC5615 HC5615 HW5615 HW5615

Steel | Steel | Steel | Steel |

Stainless steel Stainless steel Stainless steel Stainless steel Stainless steel Stainless steel

Material to be processed | Non-ferrous | Non-ferrous | Special alloy | Special alloy | Non-ferrous | Non-ferrous

metal | Cast metal | Cast | Hardened | Hardened metal metal

metal metal material material

D α Suitable for L L1 F D min. 17124... 17124... 17124... 17124... 17124... 17124...

(mm) (Degree) screw thread (mm) (mm) (mm) (mm) Ident. No. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

3 60 M4 x 0.5 39 15 1.4 3.2 300 ○ 316 ○ 332 ○ 348 ○ 364 ○ 380 ○

3 60 M4 x 0.7 39 15 1.4 3.2 302 ○ 318 ○ 334 ○ 350 ○ 366 ○ 382 ○

3 60 M4.5 x 0.75 39 15 1.4 3.2 304 ○ 320 ○ 336 ○ 352 ○ 368 ○ 384 ○

4 60 M5 x 0.5 51 15 1.8 4.1 306 ○ 322 ○ 338 ○ 354 ○ 370 ○ 386 ○

4 60 M5 x 0.75 51 15 1.8 4.1 308 ○ 324 ○ 340 ○ 356 ○ 372 ○ 388 ○

4 60 M5 x 0.8 51 15 1.8 4.1 310 ○ 326 ○ 342 ○ 358 ○ 374 ○ 390 ○

5 60 M6 x 1 51 15 2.2 4.9 312 ○ 328 ○ 344 ○ 360 ○ 376 ○ 392 ○

6 60 M8 x 1.25 51 22 2.8 6.1 314 ○ 330 ○ 346 ○ 362 ○ 378 ○ 394 ○

Prod. Gr. 1FB

Miniature cutting insert type AI

For thread turning, 55° full profi le

Application: No de-burring of thread required due to full-profi le geometry

Ident. No. 400–430: For thread cutting 55° in steel and (stainless steel) material Ident. No. 400–430:

groups at low to high cutting speeds and mid-range cutting conditions. Robust cemented carbide grade for a broad application range

Ident. No. 432–462: For thread cutting 55° in steel, stainless steel, special Ideal for use with low-performance machines and unstable cutting conditions

alloys material groups, hard machining to 65HRC at high cutting speeds and mid- Ident. No. 416–462: Exact replication of thread fl anks with exact profi le pres-

range cutting conditions. entation, no de-burring of thread required due to full-profi le geometry

Ident. No. 464–494: For 55° thread cutting in the material groups of steel and Ident. No. 432–462:

(stainless steel) with low to high cutting speeds and medium cutting conditions. Very hard cemented carbide grade ensures low wear

Execution: Innovative coating technology for universal use with very high service life

requirements

Ident. No. 400–462: Solid carbide cutting insert 55° with internal cooling Ident. No. 464–494:

Ident. No. 464–494: solid carbide 55° cutting insert with inner cooling very hard cemented carbide type ensures low wear

precise mapping of the thread fl anges with exact profi le illustration, no need

Advantage: to deburr the thread thanks to full profi le geometry

Ident. No. 400–414: extremely sharp cutting edges ensure cutting with process reliability

Exact replication of the thread fl anks with exact profi le presentation

L

> 3,2mm

D

Ident. No. 400–430 Ident. No. 432–462 Ident. No. 464–494

F

L1

p. 624

Machining direction Right Le Right Le Right Le

Carbide type HC5640 HC5640 HC5615 HC5615 HW5615 HW5615

Steel | Steel | Steel | Steel |

Stainless steel Stainless steel Stainless steel Stainless steel Stainless steel Stainless steel

Material to be processed | Non-ferrous | Non-ferrous | Special alloy | Special alloy | Non-ferrous | Non-ferrous

metal | Cast metal | Cast | Hardened | Hardened metal metal

metal metal material material

D α Suitable for screw L (mm) F (mm) D min. 17124... 17124... 17124... 17124... 17124... 17124...

(mm) (Degree) thread (mm) Ident. No. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

3 55 UNF 8”-36 39 1.4 3.2 400 ○ 416 ○ 432 ○ 448 ○ 464 ○ 480 ○

3 55 UNC 8”-32 39 1.4 3.2 402 ○ 418 ○ 434 ○ 450 ○ 466 ○ 482 ○

4 55 UNS 12”-36 51 1.8 4.1 404 ○ 420 ○ 436 ○ 452 ○ 468 ○ 484 ○

4 55 UNEF 12”-32 51 1.8 4.1 406 ○ 422 ○ 438 ○ 454 ○ 470 ○ 486 ○

5 55 UNF 1/4”-28 51 2.2 4.9 408 ○ 424 ○ 440 ○ 456 ○ 472 ○ 488 ○

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 498

0631_EN_2018_KERN[21847957]-k.indd 631 12/17/2018 3:33:12 PM