Page 43 - Industrial Tools Catalog (2)

P. 43

Mechanical clamping elements \ Mechanical clamping elements

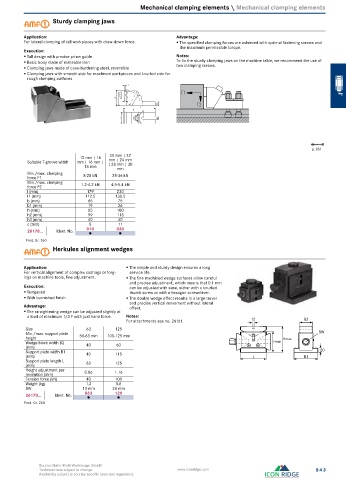

Sturdy clamping jaws

Application: Advantage:

For lateral clamping of tall workpieces with draw-down force. The specified clamping forces are achieved with optimal fastening screws and

Execution: the maximum permissible torque.

Tall design with precise prism guide Notes:

Basic body made of malleable iron To fix the sturdy clamping jaws on the machine table, we recommend the use of

Clamping jaws made of case-hardening steel, reversible two clamping screws.

Clamping jaws with smooth side for machined workpieces and knurled side for

rough clamping surfaces

p. 851

12 mm | 14 20 mm | 22

mm | 24 mm

Suitable T-groove width mm | 16 mm | | 28 mm | 30

18 mm mm

Min./max. clamping 8-28 kN 25-36 kN

force F1

Min./max. clamping 1.2-4.2 kN 4.5-5.4 kN

force F2

l (mm) 179 230

l1 (mm) 112.5 138.5

b (mm) 65 75

b1 (mm) 19 26

h (mm) 85 100

h2 (mm) 99 118

h3 (mm) 40 40

c (mm) 8 11

26178... Ident. No. 010 020

●

●

Prod. Gr. 260

Herkules alignment wedges

Application: The simple and sturdy design ensures a long

For vertical alignment of complex castings or forg- service life.

ings on machine tools, fine adjustment. The fine machined wedge surfaces allow careful

and precise adjustment, which means that 0.1 mm

Execution: can be adjusted with ease, either with a knurled

Tempered thumb screw or with a hexagon screwdriver.

With burnished finish The double wedge effect results in a large travel

Advantage: and precise vertical movement without lateral

offset.

The straightening wedge can be adjusted slightly at

a load of maximum 1/3 F with just hand force. Notes:

For attachments see no. 26161. 12 B2

Size 63 125

Min./max. support plate 50-63 mm 100-125 mm SW

height Hmax

Wedge block width B2 40 60 Hmin

(mm)

Support plate width B1 40 115 20

(mm) L B1

Support plate length L 63 125

(mm)

Height adjustment per 0.86 1.16

revolution (mm)

Tension force (kN) 40 100

Weight (kg) 1.3 8.6

SW 13 mm 24 mm

26170... Ident. No. 063 125

●

●

Prod. Gr. 260

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 843

Availability subject to country specific rules and regulations.