Page 1022 - Master Catalog 2017, Inch

P. 1022

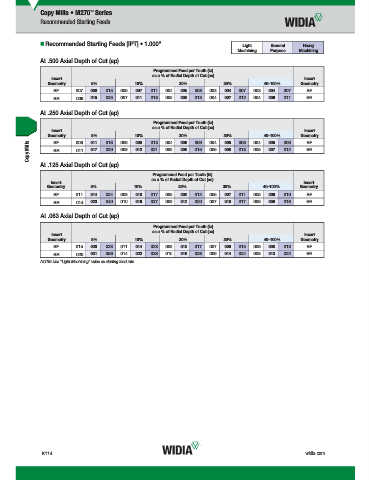

Copy Mills • M270 Series

™

Recommended Starting Feeds

Recommended Starting Feeds [IPT] • 1.000" Light General Heavy

Machining Purpose Machining

At .500 Axial Depth of Cut (ap)

Programmed Feed per Tooth (fz)

as a % of Radial Depth of Cut (ae)

Insert Insert

Geometry 5% 10% 20% 30% 40–100% Geometry

BF .007 .009 .015 .005 .007 .011 .004 .005 .008 .003 .004 .007 .003 .004 .007 BF

BR .009 .015 .025 .007 .011 .018 .005 .008 .013 .004 .007 .012 .004 .006 .011 BR

At .250 Axial Depth of Cut (ap)

Programmed Feed per Tooth (fz)

as a % of Radial Depth of Cut (ae)

Insert Insert

Geometry .008 .011 .018 .006 10% .013 .004 20% .009 .004 30% .008 .004 40–100% .008 Geometry

5%

.005

.005

BF

BF

.008

.006

Copy Mills BR .011 .017 .030 .008 .012 .021 .006 .009 .015 .005 .008 .013 .005 .007 .012 BR

At .125 Axial Depth of Cut (ap)

Programmed Feed per Tooth (fz)

as a % of Radial Depth of Cut (ae)

Insert Insert

Geometry 5% 10% 20% 30% 40–100% Geometry

BF .011 .014 .024 .008 .010 .017 .006 .008 .012 .005 .007 .011 .005 .006 .010 BF

BR .014 .023 .040 .010 .016 .027 .008 .012 .020 .007 .010 .017 .006 .009 .016 BR

At .063 Axial Depth of Cut (ap)

Programmed Feed per Tooth (fz)

as a % of Radial Depth of Cut (ae)

Insert Insert

Geometry 5% 10% 20% 30% 40–100% Geometry

BF .015 .020 .033 .011 .014 .023 .008 .010 .017 .007 .009 .015 .006 .008 .013 BF

BR .020 .031 .056 .014 .022 .038 .010 .016 .028 .009 .014 .024 .008 .013 .022 BR

NOTE: Use “Light Machining” value as starting feed rate.

K114 widia.com

V

16 I d

WID M

C

Mill K114 K115 Mi

i

bl MIlli

L WID_Master16_IndexableMIlling_CopyMills_K114_K115_Minch_REBRAND.indd 114 h REBRANDO b 14 201511 53AM 10/29/15 1:44 PM