Page 1023 - Master Catalog 2017, Inch

P. 1023

Copy Mills • M270 Series

™

Additional Application Advice • M270 Ball Nose

Selecting the Correct Insert and Cutting Conditions for Your Application

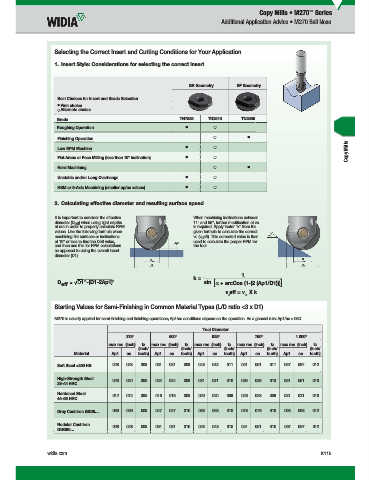

1. Insert Style: Considerations for selecting the correct insert

BR Geometry BF Geometry

Best Choices for Insert and Grade Selection

First choice

Alternate choice

Grade TN7535 TN2510 TN2505

Roughing Operation

Finishing Operation

Copy Mills

Low RPM Machine

Flat Areas or Face Milling (less than 10° inclination)

Hard Machining

Unstable and/or Long Overhangs

HSM or 5-Axis Machining (smaller ap/ae values)

2. Calculating effective diameter and resulting surface speed

It is important to consider the effective When machining inclinations between

diameter (D eff ) when using light depths 11° and 55°, further modifi cation of vc

of cut in order to properly calculate RPM is required. Apply factor “k” from the

values. Use the following formula when given formula to calculate the correct

machining fl at surfaces or inclinations vc (v eff). This corrected value is then α

c

of 10° or less to fi nd the Deff value, used to calculate the proper RPM for

Ap1

and then use this for RPM calculations the tool.

as opposed to using the overall insert

diameter (D1).

D eff D eff

D 1 D 1

1

k =

D eff 2 -(D1-2Ap1) 2 sin [α + arcCos (1-(2 (Ap1/D1)))]

v eff = v X k

c c

Starting Values for Semi-Finishing in Common Material Types (L/D ratio <3 x D1)

M270 is usually applied for semi-fi nishing and fi nishing operations; Ap1/ae conditions depend on the operation. As a general rule: Ap1/ae ).05D.

Tool Diameter

.375" .500" .625" .750" 1.000"

max rec. (inch) fz max rec. (inch) fz max rec. (inch) fz max rec. (inch) fz max rec. (inch) fz

(inch/ (inch/ (inch/ (inch/ (inch/

Material Ap1 ae tooth) Ap1 ae tooth) Ap1 ae tooth) Ap1 ae tooth) Ap1 ae tooth)

Soft Steel <250 HB .028 .028 .008 .031 .031 .008 .043 .043 .011 .051 .051 .011 .067 .067 .012

High-Strength Steel .020 .020 .006 .024 .024 .008 .031 .031 .010 .039 .039 .010 .051 .051 .010

33–44 HRC

Hardened Steel .012 .012 .006 .016 .016 .008 .020 .020 .009 .028 .028 .009 .031 .031 .010

44–55 HRC

Gray Cast Iron GG25… .039 .039 .008 .047 .047 .010 .063 .063 .010 .078 .078 .010 .098 .098 .012

Nodular Cast Iron .028 .028 .008 .031 .031 .010 .043 .043 .010 .051 .051 .010 .067 .067 .012

GGG60…

widia.com K115

WID_Master16_IndexableMIlling_CopyMills_K114_K115_Minch_REBRAND.indd 115 L V i WID M 16 I d bl MIlli C Mill K114 K115 Mi h REBRANDO b 1420151153AM

10/29/15 1:44 PM