Page 66 - APEX MRO Products

P. 66

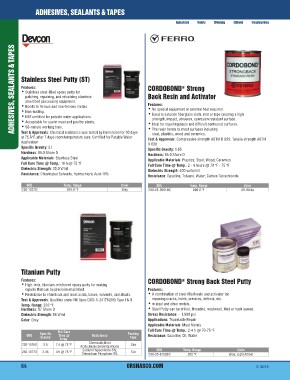

ADHESIVES, SEALANTS & TAPES

Industrial Safety Welding Oilfield Construction

ADHESIVES, SEALANTS & TAPES Stainless Steel Putty (ST) CORDOBOND® Strong

F•eaSttuarinelse:ss steel‑filled epoxy putty for Back Resin and Activator

patching, repairing, and rebuilding stainless Features:

steel food processing equipment.

• No special equipment or external heat required.

• Bonds to ferrous and non‑ferrous metals. • Used to saturate fiberglass cloth, mat or tape creating a high

• Non‑rusting.

• NSF certified for potable water applications. strength, impact, abrasion, corrosion resistant surface.

• Acceptable for use in meat and poultry plants.

• 58‑minute working time. • Ideal for repairing pipes and difficult contoured surfaces.

• The resin bonds to most surfaces including

Test & Approvals: Chemical resistance was tested by immersion for 30 days

at 75 °F, after 7 days room temperature cure; Certified for Potable Water steel, plastics, wood and ceramics.

Application Test & Approvals: Compressive strength ASTM D 695; Tensile strength ASTM

D 638

Specific Gravity: 3.1 Specific Gravity: 1.85

Hardness: 85.0 Shore D Hardness: 85.0 Shore D

Applicable Materials: Stainless Steel Applicable Materials: Plastics; Steel; Wood; Ceramics.

Full Cure Time @ Temp.: 16 h @ 75 °F Full Cure Time @ Temp.: 2 ‑ 4 hours @ 70 °F ‑ 75 °F

Dielectric Strength: 30.0 V/mil Dielectric Strength: 400 volts/mil

Resistance: Chlorinated Solvents; Hydrochloric Acid‑10% Resistance: Gasoline; Toluene; Water; Carbon Tetrachloride

SKU Temp. Range Color SKU Temp. Range Color

230‑10270 250.0 °F Grey 198‑25‑060140 200.0 °F Off‑White

Titanium Putty CORDOBOND® Strong Back Steel Putty

F•eaHtiugrhe‑ste: ch, titanium‑reinforced epoxy putty for making •FeaAtucroems:bination of steel‑filled resin and activator for

repairs that can be precision machined. repairing cracks, holes, crevices, defects, etc.

• Resistance to chemicals and most acids, bases, solvents, and alkalis. • in steel and other metals.

• Steel Putty can be drilled, threaded, machined, filed or hack sawed.

Test & Approvals: Qualifies under Mil Spec DOD‑C‑24176(SH) Type I & II

Temp. Range: 350 °F Stress Resistance: ‑ 1,800 psi

Hardness: 87 Shore D Applications: Trowelable Repair

Dielectric Strength: 56 V/mil Applicable Materials: Most Metals

Color: Grey Full Cure Time @ Temp.: 2‑4 h @ 70‑75 °F

Resistance: Gasoline; Oil; Water

SKU Specific Full Cure Resistance Packing

Gravity Time @ Chemicals;Most Type

Temp. Acids;Bases;Solvents;Alkalis Can

230‑10760 2.5 7 d @ 75 °F Sodium Hypochlorite‑5%; Tub

Triosodium Phosphate‑5%

230‑10770 2.36 4 h @ 75 °F SKU Temp. Range Color

198‑25‑810020 200 °F Gray; Light Amber

64 ORSNASCO.COM © 2016