Page 52 - baseline

P. 52

Recycling Practices cloth, bath mats, industry wipes, or oil-absorbent

mats, etc.

l Currently, recycled yarn has limited use only in

l During the visit to Panipat, one of India’s major

knitted and denim fabric at present.

recycling centres, it was seen that obsolete

l Birla Cellulose has developed a chemical recycling

technologies are being used for recycling and

process out of pre-consumer cotton waste for

re-production processes.

creating GRS certified liva reviva, a recycled

l Clothes are sorted by colour and material, while the

viscose fibre.

fibres are shredded and ripped down via

unravelling, grinding, defibration, and cutting.

Since the fibres are shortened, they become

Circularity focal points: Technology

weaker and damaged during the sorting process.

upgradation, traceability

Its functionality and quality degrade, forcing

producers to add virgin and high-quality fibres.

l Open-ended recycled yarns with a Ne count of Open-end Spinning

0s-30s are prevalent in the industry, whereas only a

few recyclers produce ring-spun recycled yarns.

It was discovered that open-end spinning industries are

l Currently, GRS certification offers access to the

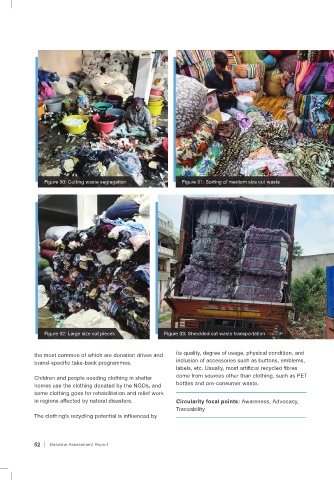

Figure 30: Cutting waste segregation Figure 31: Sorting of medium size cut waste located in major recycling hubs of India and source pre-

formal economy for recycled textiles. The existing

and post-consumer waste through waste collectors/

technological barrier permits 30% recycled fibres

middlemen spread across different clusters of India.

to be substituted for natural fibres. Impurities in the

input material further diminish the grade of recycled

Natural fibres such as cotton fabrics are primarily

fibres.

recovered through mechanical recycling and are spun

l Due to mechanical recycling limitations, fiber

into coarser yarn using open-end spinning.

characteristics deteriorate, however better

recycling value can be perceived from knitted (100

As the bales are cut open, the mutilated garments are

% cotton solid colors) as compared to woven.

sorted colour-wise and stripped of all accessories,

l The recycled yarn is down cycled based on their

such as labels, buttons, zippers, press studs, leather

coarseness and used in manufacturing of products

such as insulating materials, industrial cleaning

Figure 34: OE spinning PFD

Figure 32: Large size cut pieces Figure 33: Shredded cut waste transportation

its quality, degree of usage, physical condition, and

the most common of which are donation drives and

inclusion of accessories such as buttons, emblems,

brand-specific take-back programmes.

labels, etc. Usually, most artificial recycled fibres

come from sources other than clothing, such as PET

Children and people needing clothing in shelter

bottles and pre-consumer waste.

homes use the clothing donated by the NGOs, and

some clothing goes for rehabilitation and relief work

in regions affected by natural disasters. Circularity focal points: Awareness, Advocacy,

Traceability

The clothing’s recycling potential is influenced by

1. Raw Material 2. Disassembly 3. Sorting

52 Baseline Assessment Report Baseline Assessment Report 53