Page 22 - Fredo Eyong

P. 22

DESCRIPTION Reflection

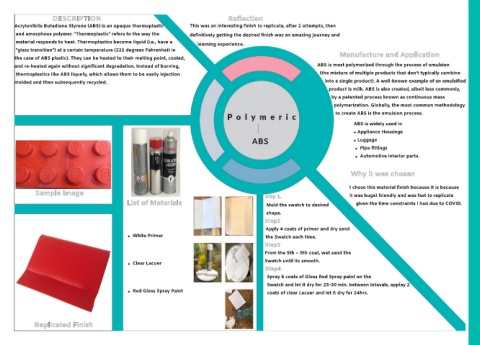

Acrylonitrile Butadiene Styrene (ABS) is an opaque thermoplastic This was an interesting finish to replicate, after 2 attempts, then

and amorphous polymer. “Thermoplastic” refers to the way the definitively getting the desired finish was an amazing journey and

material responds to heat. Thermoplastics become liquid (i.e., have a

learning experience.

“glass transition”) at a certain temperature (221 degrees Fahrenheit in

Manufacture and Application

the case of ABS plastic). They can be heated to their melting point, cooled,

and re-heated again without significant degradation. Instead of burning, ABS is most polymerized through the process of emulsion

thermoplastics like ABS liquefy, which allows them to be easily injection (the mixture of multiple products that don’t typically combine

molded and then subsequently recycled. into a single product). A well-known example of an emulsified

product is milk. ABS is also created, albeit less commonly,

by a patented process known as continuous mass

polymerization. Globally, the most common methodology

P olymeric to create ABS is the emulsion process.

ABS is widely used in

. Appliance Housings

ABS . Luggage

. Pipe fittings

. Automotive interior parts.

Why it was chosen

I chose this material finish because it is because

Sample Image Step 1. it was buget friendly and was fast to replicate

List of Materials Mold the swatch to desired given the time constraints i had due to COVID.

shape.

Step2

Apply 4 coats of primer and dry sand

. White Primer the Swatch each time.

Step3

From the 5th – 9th coat, wet sand the

Swatch until its smooth.

. Clear Lacuer

Step4

Spray 6 coats of Gloss Red Spray paint on the

Swatch and let it dry for 25-30 min. between intavals, applay 2

. Red Gloss Spray Paint coats of clear Lacuer and let it dry for 24hrs.

Replicated Finish