Page 66 - Maeve Whelan

P. 66

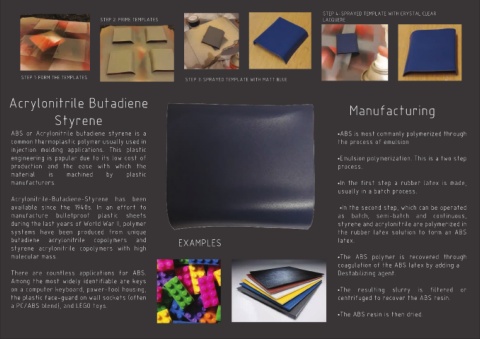

STEP 4: SPRAYED TEMPLATE WITH CRYSTAL CLEAR

STEP 2: PRIME TEMPLATES LACQUERE

STEP 1: FORM THE TEMPLATES STEP 3: SPRAYED TEMPLATE WITH MATT BLUE

Manufacturing Acrylonitrile Butadiene Manufacturing

Styrene

•Creating carbon fibre involves both ABS or Acrylonitrile butadiene styrene is a •ABS is most commonly polymerized through

chemical and mechanical processes. common thermoplastic polymer usually used in the process of emulsion

injection molding applications. This plastic

•It begins by drawing long fiber strands and engineering is popular due to its low cost of •Emulsion polymerization. This is a two step

then heating them at a very high production and the ease with which the process.

temperature without allowing oxygen to material is machined by plastic

come into contact, to prevent the fibers manufacturers. •In the first step a rubber latex is made,

from burning. usually in a batch process.

Acrylonitrile-Butadiene-Styrene has been

•This is when carbonization happens, which available since the 1940s. In an effort to •In the second step, which can be operated

is when the atoms within the fibers vibrate manufacture bulletproof plastic sheets as batch, semi-batch and continuous,

violently, expelling most non-carbon atoms. during the last years of World War II, polymer styrene and acrylonitrile are polymerized in

systems have been produced from unique the rubber latex solution to form an ABS

•This leaves a fiber made up of long, tightly butadiene acrylonitrile copolymers and EXAMPLES latex.

interlocked chains of carbon atoms with styrene acrylonitrile copolymers with high

just a few non-carbons. molecular mass. •The ABS polymer is recovered through

coagulation of the ABS latex by adding a

•A typical sequences used to form carbon There are countless applications for ABS. Destabilizing agent.

fibers from polyacrylonitrile involves Among the most widely identifiable are keys

spinning, stabilizing, carbonizing, treating on a computer keyboard, power-tool housing, •The resulting slurry is filtered or

the surface and sizing. the plastic face-guard on wall sockets (often centrifuged to recover the ABS resin.

a PC/ABS blend), and LEGO toys.

•The ABS resin is then dried.