Page 67 - Maeve Whelan

P. 67

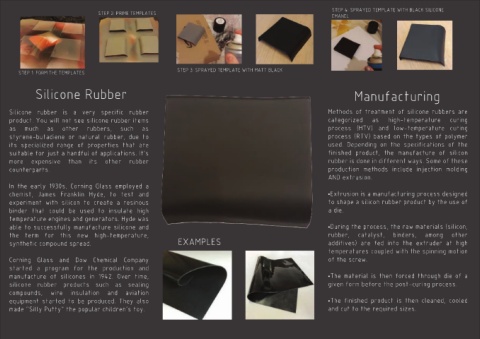

STEP 4: SPRAYED TEMPLATE WITH BLACK SILICONE

STEP 2: PRIME TEMPLATES

EMANEL

STEP 3: SPRAYED TEMPLATE WITH MATT BLACK

STEP 1: FORM THE TEMPLATES

Silicone Rubber Manufacturing

Silicone rubber is a very specific rubber Methods of treatment of silicone rubbers are

product. You will not see silicone rubber items categorized as high-temperature curing

as much as other rubbers, such as process (HTV) and low-temperature curing

styrene-butadiene or natural rubber, due to process (RTV) based on the types of polymer

its specialized range of properties that are used. Depending on the specifications of the

suitable for just a handful of applications. It's finished product, the manufacture of silicon

more expensive than its other rubber rubber is done in different ways. Some of these

counterparts. production methods include injection molding

AND extrusion.

In the early 1930s, Corning Glass employed a

chemist, James Franklin Hyde, to test and •Extrusion is a manufacturing process designed

experiment with silicon to create a resinous to shape a silicon rubber product by the use of

binder that could be used to insulate high a die.

temperature engines and generators. Hyde was

able to successfully manufacture silicone and •During the process, the raw materials (silicon,

the term for this new high-temperature, rubber, catalyst, binders, among other

synthetic compound spread. EXAMPLES additives) are fed into the extruder at high

temperatures coupled with the spinning motion

Corning Glass and Dow Chemical Company of the screw.

started a program for the production and

manufacture of silicones in 1942. Over time, •The material is then forced through die of a

silicone rubber products such as sealing given form before the post-curing process.

compounds, wire insulation and aviation

equipment started to be produced. They also •The finished product is then cleaned, cooled

made "Silly Putty" the popular children's toy. and cut to the required sizes.