Page 69 - Maeve Whelan

P. 69

Trial and Error

Through my process of creating swatches for this project I discovered many different techniques to

get my desired finish, I learned these however through trial and error.

Copper

Not much went wrong while making my copper swatch, however when I first attempted to create the

weathered effect on the copper spray I had watered down the poster paint too much and had no

effect on the swatch, after adding more paint it thickened the substance and gave the swatch the

effect I wanted.

The success of wood manufacturing rests on the mill’s ability

to retain the wood’s quality throughout the manufacturing

process. Carbon Fibre

My first attempt at my carbon fibre was a disaster, I had my matte black base coat down, however

•Edging: Removing irregular edges and defects from sawn when I went to apply the silver for the desired affect, the shelf liner I was using moved and I needed

pieces. to respray the matte black as the silver had smudged across the swatch. My seconded attempt was BIRCH WOOD GRAIN; FIRST ATTEMPT

much better as I had properly secured the shelf liner down.

•Trimming: The trimmer squares off the ends of lumber into

uniform pieces based on market dimensions.

Blue abs

•Rough Lumber Sorting: Pieces are segregated based on When doing my blue abs, everything was perfect up till the end, I had my blue coat on and I had

dimension and final product production: unseasoned (known as sprayed on my final coat of crystal clear lacquer, I however didn't properly store my swatch and

green), or dry. pieces of fluff and dust stuck onto the coat and I had to restart the swatch.

•Stickering: Lumber destined for dry production is stacked

with spacers (known as stickers) that allow air to circulate Silicone rubber

within the stack. (Green product skips this stage). While nothing went wrong while doing this swatch, I didn't quite like the end result, it looks like

silicone rubber but looks too plain in my opinion. Perhaps a coat of clear coat would make it look

•Drying: Lumber is kiln-dried to facilitate natural MC better, or some kind of crackled effect?

evaporation.

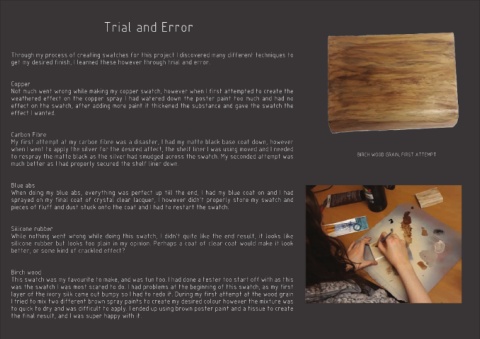

•Planning: Smoothing the surface of each lumber piece and Birch wood

making its width and thickness uniform. This swatch was my favourite to make, and was fun too. I had done a tester too start off with as this

was the swatch I was most scared to do. I had problems at the beginning of this swatch, as my first

layer of the ivory silk came out bumpy so I had to redo it. During my first attempt at the wood grain

•Grading: The process of assessing the characteristics of I tried to mix two different brown spray paints to create my desired colour however the mixture was

each lumber piece in order to assign its “grade” (quality). to quick to dry and was difficult to apply. I ended up using brown poster paint and a tissue to create

the final result, and I was super happy with it.