Page 21 - John F Hunt Group Newsletter - SEP 2023

P. 21

BD Nuclear Fort Gilkicker Redevelopment!

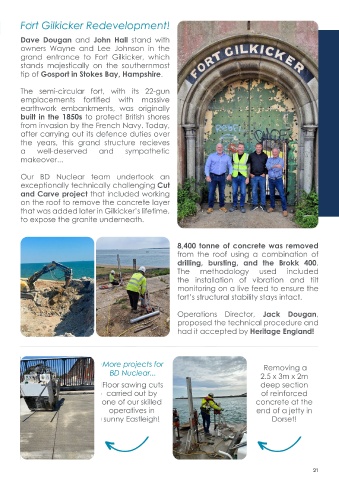

Dave Dougan and John Hall stand with

The BD Nuclear team have been as busy as ever! Check out just some of our top jobs owners Wayne and Lee Johnson in the

since the last newsletter... grand entrance to Fort Gilkicker, which

stands majestically on the southernmost

West Sussex Fire Station and tip of Gosport in Stokes Bay, Hampshire.

Training Centre... The semi-circular fort, with its 22-gun

On this job, we were approached by a emplacements fortified with massive

company to assist with installing fireproof earthwork embankments, was originally

tiles for the new state-of-the-art training built in the 1850s to protect British shores

facility at Horsham Fire Station. from invasion by the French Navy. Today,

after carrying out its defence duties over

This fantastic new facility provides a the years, this grand structure recieves

highly modern training centre, working a well-deserved and sympathetic

environment for staff members, and a makeover...

24-hour operational fire station.

Our BD Nuclear team undertook an

exceptionally technically challenging Cut

Diamond Wire Sawing for and Carve project that included working

on the roof to remove the concrete layer

Northwest Galvanizing... that was added later in Gilkicker’s lifetime,

With this job, the metal finishing company to expose the granite underneath.

Northwest Galvanizing had an issue with

one of their galvanising baths that had

started to leak, leaving an abnormally 8,400 tonne of concrete was removed

high amount of material to solidify at the from the roof using a combination of

bottom. When the old bath was removed drilling, bursting, and the Brokk 400.

and replaced, 110 tonnes of material The methodology used included

was left! the installation of vibration and tilt

monitoring on a live feed to ensure the

BD Nuclear’s team were tasked with fort’s structural stability stays intact.

cutting 46 sections of 1.2m x 1.2m x

0.350mm, each weighing approximately Operations Director, Jack Dougan,

2 tonnes. They used the portal diamond proposed the technical procedure and

wire saw for this process, which saw cuts had it accepted by Heritage England!

vertically and horizontally.

The material in the bath was steel-zinc-

lead, which proved to be very difficult More projects for Removing a

to cut due to the softness of the lead. BD Nuclear... 2.5 x 3m x 2m

Floor sawing cuts deep section

This was overcome by using past carried out by of reinforced

experiences in nuclear power stations one of our skilled concrete at the

cutting lead. The job was a great operatives in end of a jetty in

success, resulting in a very happy client! sunny Eastleigh! Dorset!

There is alot going on behind the scenes at BD Nuclear and we have BIG news

coming soon! You can stay updated by following us on LinkedIn

20 21