Page 24 - December

P. 24

PROFESSIONAL ADVICE PROFESSIONAL ADVICE

Application of industrial robots in construction Fig. 2. An example of a large-panel The complex consists of two industrial

formwork frame

robots, two welding positioners with a

Lack of qualified specialists, low labor productivity at traditional technology for the lifting capacity of 1.5 tons each, two

manufacture of structures, obsolete equipment negatively affect the production activities of sets of reconfigurable technological

enterprises related to construction. However, the impact of these factors can be significantly equipment, welding and auxiliary

reduced by using modern industrial robots in equipment. In the process of work, the

technological processes, in particular, robotic complex is serviced by two workers, one of whom

It is known that technological complexes

complexes for assembly-welding of large- with industrial robots are expensive. The is an operator-adjuster.

panel formwork and embedded products. The product is welded in the following sequence:

high cost of a robotic complex is determined ● workers install the component parts of the product to

either by a high degree of adaptability of the be welded into the technological equipment and fix them with

robot control system, or by the presence of pneumatic clamps;

complex and expensive additional equipment ● after making sure that there are parts in the equipment and that

that ensures the functioning of robots with a there are no people in the working area of the robots, the operator starts

low degree of adaptation. In particular, industrial robots received widespread in the automotive the welding program from the control panel of the complex;

industry for the assembly and welding of car body structures. ● the product is welded by robots, at this time, at the second working position, workers install

Large volumes of production of technically complex facilities, the implementation of the parts into the tooling;

unmanned technological processes, high quality products justify the costs of designing, ● after the end of welding, the robots turn to the second position. In the first position, workers

manufacturing and operating complex and expensive robotic systems. remove the finished product from the tooling and reload the composite parts. The cycle is

But, as practice shows, the use of industrial robots is also effective in the production repeated.

of relatively simple structures with human participation in the technological process. In the The design of the technological equipment used in this complex allows you to adjust to

examples of the use of such robotic systems given in the article, technologies are implemented 16 standard sizes of products with a step in width of 50 mm, which makes production more

in which welding operations are carried out by industrial robots, and auxiliary operations flexible, satisfies the market needs in full. Thanks to the use of modern welding equipment,

are performed by low-skilled workers. At the enterprise for the manufacture of large-panel together with the optimal algorithms for the operation of the robotic complex, the production

formwork, problems arose associated with the lack of qualified welders and, as a result, low time for one frame is 8 minutes, which allows the production of up to 50 products per shift,

productivity of the technological process. The introduction of a relatively simple robotic complex with no scrap. As a result of the introduction of the complex, labor productivity has increased

made it possible to solve the problem at a relatively low cost of the complex. more than threefold, the enterprise got rid of the problem of a shortage of qualified welders.

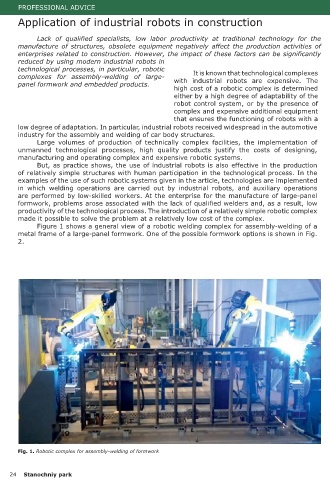

Figure 1 shows a general view of a robotic welding complex for assembly-welding of a The number of workers employed in the production of these products has decreased by 30%.

metal frame of a large-panel formwork. One of the possible formwork options is shown in Fig. The profit received after the implementation of the complex allowed the company to acquire

2. two more similar complexes in two years. A robotic complex for welding of building embedded

structures has been introduced at an enterprise in the city of Serpukhov. The general view of

the complex is shown in Fig. 3.

Fig. 1. Robotic complex for assembly-welding of formwork Fig. 3. Robotic complex for welding embedded products.

24 Stanochniy park Stanochniy park 25