Page 482 - Fundamentals of Management Myths Debunked (2017)_Flat

P. 482

CHAPTER 15 • Operations Management 481

◂ ◂ ◂ From the Past to the Present ▸ ▸ ▸

William Edwards Deming was an American statistician, • Deal with the best and fewest number of suppliers.

20

professor, author, lecturer, and consultant. He is widely • Find out whether your problems are confined to particular

credited with improving production in the United States parts of the production process or stem from the overall

during World War II, although he’s probably best known for process itself.

his work in Japan. From 1950 onward, he taught Japanese • Train workers for the job that you are asking them to

top managers how to improve product design and product perform.

quality, testing, and sales, primarily through applying statis-

tical methods. Dr. Deming’s philosophy was quite simple: • Raise the quality of your line supervisors.

Focus on increasing quality and reducing costs through • Drive out fear.

continually improving how employees’ work is done and by • Encourage departments to work closely together

approaching manufacturing in an orderly, systematic, and rather than to concentrate on departmental or divisional

logical way. distinctions.

• Do not adopt strictly numerical goals.

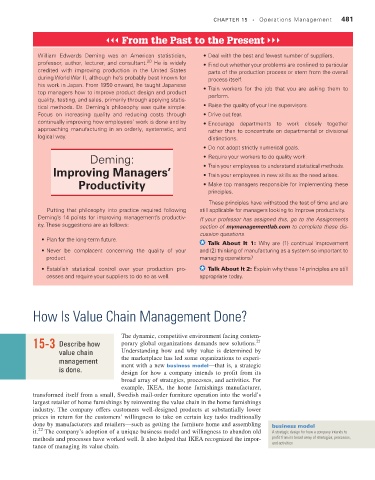

Deming: • Require your workers to do quality work.

Improving Managers’ • Train your employees to understand statistical methods.

• Train your employees in new skills as the need arises.

Productivity • Make top managers responsible for implementing these

principles.

These principles have withstood the test of time and are

Putting that philosophy into practice required following still applicable for managers looking to improve productivity.

Deming’s 14 points for improving management’s productiv- If your professor has assigned this, go to the Assignments

ity. These suggestions are as follows: section of mymanagementlab.com to complete these dis-

cussion questions.

• Plan for the long-term future.

Talk About It 1: Why are (1) continual improvement

• Never be complacent concerning the quality of your and (2) thinking of manufacturing as a system so important to

product. managing operations?

• Establish statistical control over your production pro- Talk About It 2: Explain why these 14 principles are still

cesses and require your suppliers to do so as well. appropriate today.

How Is Value Chain Management Done?

The dynamic, competitive environment facing contem-

15-3 Describe how porary global organizations demands new solutions.

21

value chain Understanding how and why value is determined by

management the marketplace has led some organizations to experi-

ment with a new business model—that is, a strategic

is done. design for how a company intends to profit from its

broad array of strategies, processes, and activities. For

example, IKEA, the home furnishings manufacturer,

transformed itself from a small, Swedish mail-order furniture operation into the world’s

largest retailer of home furnishings by reinventing the value chain in the home furnishings

industry. The company offers customers well-designed products at substantially lower

prices in return for the customers’ willingness to take on certain key tasks traditionally

done by manufacturers and retailers—such as getting the furniture home and assembling business model

22

it. The company’s adoption of a unique business model and willingness to abandon old A strategic design for how a company intends to

methods and processes have worked well. It also helped that IKEA recognized the impor- profit from its broad array of strategies, processes,

tance of managing its value chain. and activities