Page 11 - TNT_placeholder

P. 11

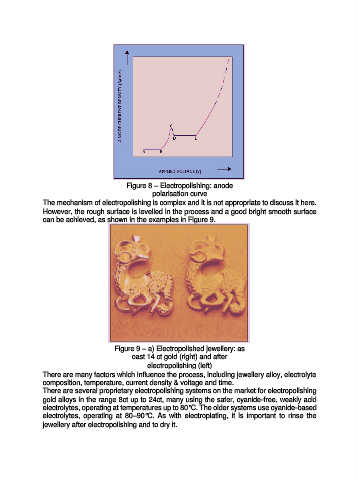

Figure 8 – Electropolishing: anode

polarisation curve

The mechanism of electropolishing is complex and it is not appropriate to discuss it here.

However, the rough surface is levelled in the process and a good bright smooth surface

can be achieved, as shown in the examples in Figure 9.

Figure 9 – a) Electropolished jewellery: as

cast 14 ct gold (right) and after

electropolishing (left)

There are many factors which influence the process, including jewellery alloy, electrolyte

composition, temperature, current density & voltage and time.

There are several proprietary electropolishing systems on the market for electropolishing

gold alloys in the range 8ct up to 24ct, many using the safer, cyanide-free, weakly acid

electrolytes, operating at temperatures up to 80°C. The older systems use cyanide-based

electrolytes, operating at 80–90°C. As with electroplating, it is important to rinse the

jewellery after electropolishing and to dry it.