Page 6 - TNT_placeholder

P. 6

Safety and Pollution Aspects

Many electrolytes are based on cyanide. This is particularly true for gold. Cyanide is very

poisonous and must be handled with great care.

A golden rule is never to allow drinking and eating in an electroplating facility and to have

very strict control and procedures in the plating shop. Protective overalls and visors

should be worn and changed regularly. Cleanliness is vital. For safety, cyanide

electrolytes and plating salts should be kept in locked cupboards. Keep cyanides and

acids apart from each other. Acid will react with cyanide to liberate deadly hydrogen

cyanide gas!

Old electrolytes, as well as cleaners and rinse waters must be disposed of safely and

NOT thrown away down the sink or drain. The consequences of doing so are too awful to

contemplate!

Acid based, non-cyanide electrolytes must also be handled with care.

All reputable salt or electrolyte manufacturers will provide Materials Safety Data

Sheets on their products and give good advice on health and safety procedures

Gold Electroplating Systems

There are many electroplating systems on the market for putting pure gold and gold alloy

deposits on to gold jewellery and on to base metals for decorative applications. There are

also many others for technical applications such as electrical contacts and connectors,

where the coating properties must have a certain technical performance.

The electrolytes can be classified into cyanide and non-cyanide based and may contain

small alloying additions to control colour and other properties. All cyanide-based

electrolytes are based on the use of gold potassium cyanide salt, KAu(CN)2, which

contains about 68% gold. However, most electrolytes do not contain anything like this

concentration of gold. Some electrolytes are acid, others neutral and others are alkaline,

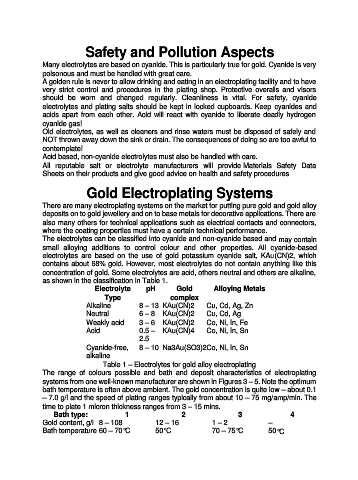

as shown in the classification in Table 1.

Electrolyte pH Gold Alloying Metals

Type complex

Alkaline 8 – 13 KAu(CN)2 Cu, Cd, Ag, Zn

Neutral 6 – 8 KAu(CN)2 Cu, Cd, Ag

Weakly acid 3 – 6 KAu(CN)2 Co, Ni, In, Fe

Acid 0.5 – KAu(CN)4 Co, Ni, In, Sn

2.5

Cyanide-free, 8 – 10 Na3Au(SO3)2 Co, Ni, In, Sn

alkaline

Table 1 – Electrolytes for gold alloy electroplating

The range of colours possible and bath and deposit characteristics of electroplating

systems from one well-known manufacturer are shown in Figures 3 – 5. Note the optimum

bath temperature is often above ambient. The gold concentration is quite low – about 0.1

– 7.0 g/l and the speed of plating ranges typically from about 10 – 75 mg/amp/min. The

time to plate 1 micron thickness ranges from 3 – 15 mins.

Bath type: 1 2 3 4

Gold content, g/l 8 – 108 12 – 16 1 – 2 –

Bath temperature 60 – 70°C 50°C 70 – 75°C 50°C