Page 7 - TNT_placeholder

P. 7

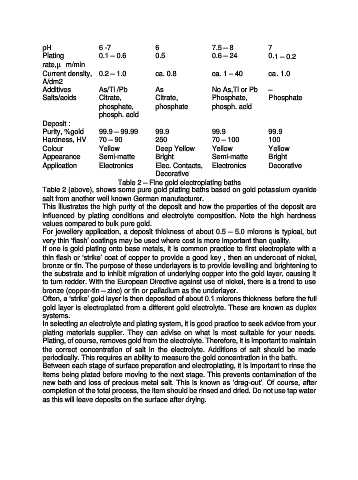

pH 6 -7 6 7.5 – 8 7

Plating 0.1 – 0.6 0.5 0.6 – 24 0.1 – 0.2

rate,µ m/min

Current density, 0.2 – 1.0 ca. 0.8 ca. 1 – 40 ca. 1.0

A/dm2

Additives As/Ti /Pb As No As,Ti or Pb –

Salts/acids Citrate, Citrate, Phosphate, Phosphate

phosphate, phosphate phosph. acid

phosph. acid

Deposit :

Purity, %gold 99.9 – 99.99 99.9 99.9 99.9

Hardness, HV 70 – 90 250 70 – 100 100

Colour Yellow Deep Yellow Yellow Yellow

Appearance Semi-matte Bright Semi-matte Bright

Application Electronics Elec. Contacts, Electronics Decorative

Decorative

Table 2 – Fine gold electroplating baths

Table 2 (above), shows some pure gold plating baths based on gold potassium cyanide

salt from another well known German manufacturer.

This illustrates the high purity of the deposit and how the properties of the deposit are

influenced by plating conditions and electrolyte composition. Note the high hardness

values compared to bulk pure gold.

For jewellery application, a deposit thickness of about 0.5 – 5.0 microns is typical, but

very thin ‘flash’ coatings may be used where cost is more important than quality.

If one is gold plating onto base metals, it is common practice to first electroplate with a

thin flash or ‘strike’ coat of copper to provide a good key , then an undercoat of nickel,

bronze or tin. The purpose of these underlayers is to provide levelling and brightening to

the substrate and to inhibit migration of underlying copper into the gold layer, causing it

to turn redder. With the European Directive against use of nickel, there is a trend to use

bronze (copper-tin – zinc) or tin or palladium as the underlayer.

Often, a ‘strike’ gold layer is then deposited of about 0.1 microns thickness before the full

gold layer is electroplated from a different gold electrolyte. These are known as duplex

systems.

In selecting an electrolyte and plating system, it is good practice to seek advice from your

plating materials supplier. They can advise on what is most suitable for your needs.

Plating, of course, removes gold from the electrolyte. Therefore, it is important to maintain

the correct concentration of salt in the electrolyte. Additions of salt should be made

periodically. This requires an ability to measure the gold concentration in the bath.

Between each stage of surface preparation and electroplating, it is important to rinse the

items being plated before moving to the next stage. This prevents contamination of the

new bath and loss of precious metal salt. This is known as ‘drag-out’. Of course, after

completion of the total process, the item should be rinsed and dried. Do not use tap water

as this will leave deposits on the surface after drying.