Page 160 - Towards A Sustainable Future 2024

P. 160

3. Analysis of failure modes: 6. Schedule Maintenance:

An analysis of failure modes to identify recurring patterns or Maintenance managers can use the insights provided by

trends that indicate potential system failures. predictive maintenance software to schedule maintenance

activities proactively. Manufacturers benefit from predictive

4. Installation of IoT Devices: maintenance through cost savings and improved operational

IoT devices such as current monitors are installed on the efficiency.

machinery to collect real-time data. Based on the gathered

data, these devices leverage sophisticated analytics to Implementing these steps can result in a predictive

predict when a failure is likely to occur. maintenance strategy that enhances asset reliability, reduces

maintenance costs, and maximises operational efficiency.

5. Utilise Machine Learning: The ESI team developed a proactive prototype sensor as an

Machine learning algorithms to analyse the collected eco-solution for predictive maintenance at Silversteel.

data and predict when maintenance is required. They can

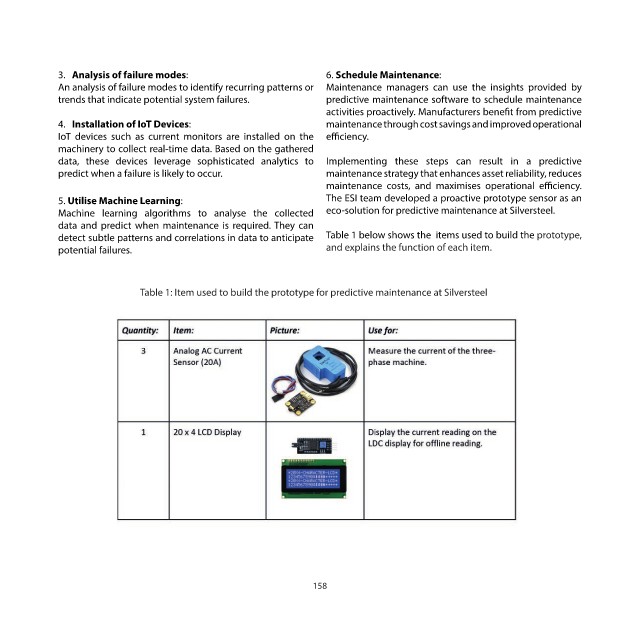

detect subtle patterns and correlations in data to anticipate Table 1 below shows the items used to build the prototype,

potential failures. and explains the function of each item.

Table 1: Item used to build the prototype for predictive maintenance at Silversteel

158