Page 163 - Towards A Sustainable Future 2024

P. 163

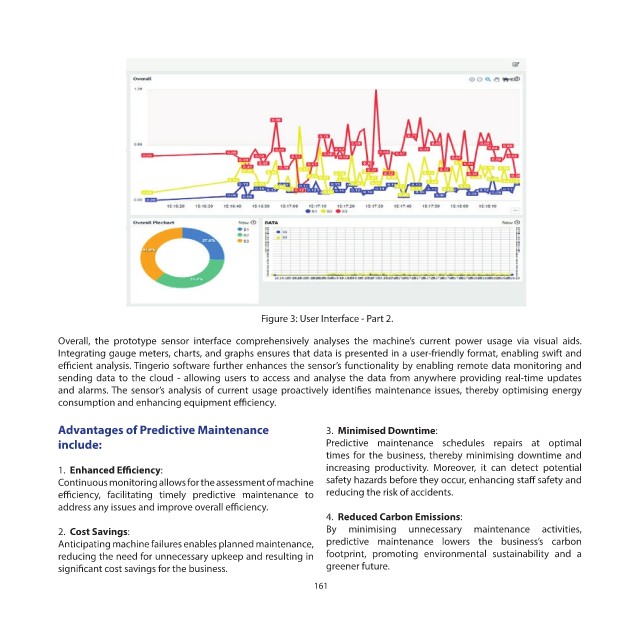

Figure 3: User Interface - Part 2.

Overall, the prototype sensor interface comprehensively analyses the machine’s current power usage via visual aids.

Integrating gauge meters, charts, and graphs ensures that data is presented in a user-friendly format, enabling swift and

efficient analysis. Tingerio software further enhances the sensor’s functionality by enabling remote data monitoring and

sending data to the cloud - allowing users to access and analyse the data from anywhere providing real-time updates

and alarms. The sensor’s analysis of current usage proactively identifies maintenance issues, thereby optimising energy

consumption and enhancing equipment efficiency.

Advantages of Predictive Maintenance 3. Minimised Downtime:

include: Predictive maintenance schedules repairs at optimal

times for the business, thereby minimising downtime and

1. Enhanced Efficiency: increasing productivity. Moreover, it can detect potential

Continuous monitoring allows for the assessment of machine safety hazards before they occur, enhancing staff safety and

efficiency, facilitating timely predictive maintenance to reducing the risk of accidents.

address any issues and improve overall efficiency.

4. Reduced Carbon Emissions:

2. Cost Savings: By minimising unnecessary maintenance activities,

Anticipating machine failures enables planned maintenance, predictive maintenance lowers the business’s carbon

reducing the need for unnecessary upkeep and resulting in footprint, promoting environmental sustainability and a

significant cost savings for the business. greener future.

161