Page 164 - Towards A Sustainable Future 2024

P. 164

Presentation of Data Conclusion

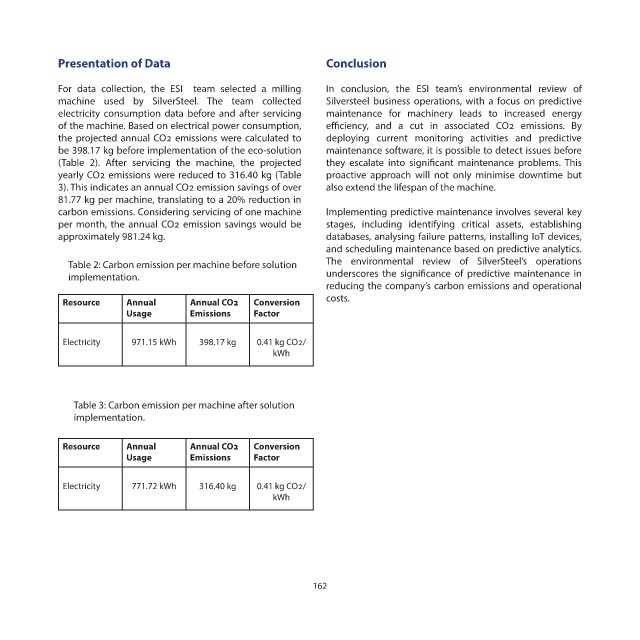

For data collection, the ESI team selected a milling In conclusion, the ESI team’s environmental review of

machine used by SilverSteel. The team collected Silversteel business operations, with a focus on predictive

electricity consumption data before and after servicing maintenance for machinery leads to increased energy

of the machine. Based on electrical power consumption, efficiency, and a cut in associated CO2 emissions. By

the projected annual CO2 emissions were calculated to deploying current monitoring activities and predictive

be 398.17 kg before implementation of the eco-solution maintenance software, it is possible to detect issues before

(Table 2). After servicing the machine, the projected they escalate into significant maintenance problems. This

yearly CO2 emissions were reduced to 316.40 kg (Table proactive approach will not only minimise downtime but

3). This indicates an annual CO2 emission savings of over also extend the lifespan of the machine.

81.77 kg per machine, translating to a 20% reduction in

carbon emissions. Considering servicing of one machine Implementing predictive maintenance involves several key

per month, the annual CO2 emission savings would be stages, including identifying critical assets, establishing

approximately 981.24 kg. databases, analysing failure patterns, installing IoT devices,

and scheduling maintenance based on predictive analytics.

Table 2: Carbon emission per machine before solution The environmental review of SilverSteel’s operations

implementation. underscores the significance of predictive maintenance in

reducing the company’s carbon emissions and operational

Resource Annual Annual CO2 Conversion costs.

Usage Emissions Factor

Electricity 971.15 kWh 398.17 kg 0.41 kg CO2/

kWh

Table 3: Carbon emission per machine after solution

implementation.

Resource Annual Annual CO2 Conversion

Usage Emissions Factor

Electricity 771.72 kWh 316.40 kg 0.41 kg CO2/

kWh

162