Page 9 - Machine Vision Presentation

P. 9

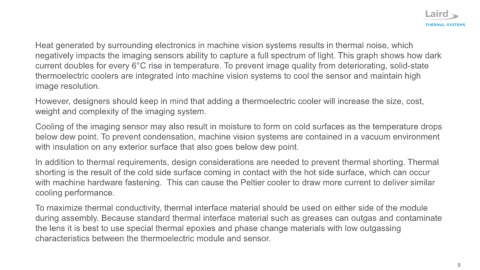

Heat generated by surrounding electronics in machine vision systems results in thermal noise, which

negatively impacts the imaging sensors ability to capture a full spectrum of light. This graph shows how dark

current doubles for every 6°C rise in temperature. To prevent image quality from deteriorating, solid-state

thermoelectric coolers are integrated into machine vision systems to cool the sensor and maintain high

image resolution.

However, designers should keep in mind that adding a thermoelectric cooler will increase the size, cost,

weight and complexity of the imaging system.

Cooling of the imaging sensor may also result in moisture to form on cold surfaces as the temperature drops

below dew point. To prevent condensation, machine vision systems are contained in a vacuum environment

with insulation on any exterior surface that also goes below dew point.

In addition to thermal requirements, design considerations are needed to prevent thermal shorting. Thermal

shorting is the result of the cold side surface coming in contact with the hot side surface, which can occur

with machine hardware fastening. This can cause the Peltier cooler to draw more current to deliver similar

cooling performance.

To maximize thermal conductivity, thermal interface material should be used on either side of the module

during assembly. Because standard thermal interface material such as greases can outgas and contaminate

the lens it is best to use special thermal epoxies and phase change materials with low outgassing

characteristics between the thermoelectric module and sensor.

9