Page 50 - QR CIMAR LASER SCREED

P. 50

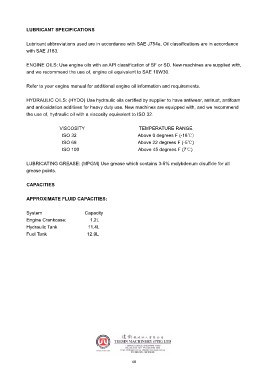

LUBRICANT SPECIFICATIONS

Lubricant abbreviations used are in accordance with SAE J754a. Oil classifications are in accordance

with SAE J183.

ENGINE OILS: Use engine oils with an API classification of SF or SD. New machines are supplied with,

and we recommend the use of, engine oil equivalent to SAE 10W30.

Refer to your engine manual for additional engine oil information and requirements.

HYDRAULIC OILS: (HYDO) Use hydraulic oils certified by supplier to have antiwear, antirust, antifoam

and antioxidation additives for heavy duty use. New machines are equipped with, and we recommend

the use of, hydraulic oil with a viscosity equivalent to ISO 32.

VISCOSITY TEMPERATURE RANGE

ISO 32 Above 0 degrees F (-18℃)

ISO 68 Above 22 degrees F (-5℃)

ISO 100 Above 45 degrees F (7℃)

LUBRICATING GREASE: (MPGM) Use grease which contains 3-5% molybdenum disulfide for all

grease points.

CAPACITIES

APPROXIMATE FLUID CAPACITIES:

System Capacity

Engine Crankcase: 1.2L

Hydraulic Tank 11.4L

Fuel Tank

12.9L

48