Page 119 - QR KLINDEX EXPANDER850AT-RXt

P. 119

OPERATION

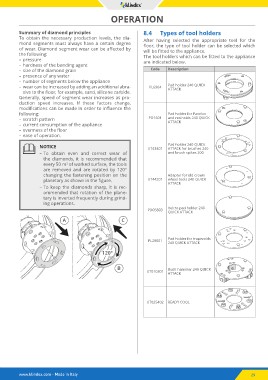

Summary of diamond principles 8.4 Types of tool holders

To obtain the necessary production levels, the dia-

mond segments must always have a certain degree After having selected the appropriate tool for the

of wear. Diamond segment wear can be affected by floor, the type of tool holder can be selected which

the following: will be fitted to the appliance.

– pressure The tool holders which can be fitted to the appliance

– hardness of the bonding agent are indicated below.

– size of the diamond grain

– presence of any water Code Description

– number of segments below the appliance

– wear can be increased by adding an additional abra- PL6904 Pad holder 240 QUICK

ATTACK

sive to the floor, for example, sand, silicone carbide.

Generally, speed of segment wear increases as pro- PD1601 Pad holder for Pavelux

duction speed increases. If these factors change, and resinoids 240 QUICK

modifications can be made in order to influence the ATTACK

following:

– scratch pattern

– current consumption of the appliance

– evenness of the floor

– ease of operation.

l NOTICE UT43401 Pad holder 240 QUICK

ATTACK for brushes 240

– To obtain even and correct wear of and brush spikes 200

the diamonds, it is recommended that

every 50 m2 of worked surface, the tools UT44201 Adapter for old crown

are removed and are rotated by 120° wheel tools 240 QUICK

changing the fastening position on the ATTACK

planetary as shown in the figure.

– To keep the diamonds sharp, it is rec-

ommended that rotation of the plane-

tary is inverted frequently during grind-

ing operations.

PD05803 Velcro pad holder 240

QUICK ATTACK

AC

PL28001 Pad holder for trapezoids

240 QUICK ATTACK

120° UT010301 Bush hammer 240 QUICK

B ATTACK

UT025402 READY COOL

www.klindex.com - Made in Italy 29