Page 59 - SSAB Welding Handbook Edition 2

P. 59

©2009-2019 by SSAB Group of companies (SSAB). All rights reserved. Only digital PDF file. No distribution. No printing allowed!

No part of this handbook may be reproduced in any form or by any means without permission in writing from SSAB.

Welding handbook 11.0 Cutting of Weldox and Hardox

11.0 Cutting of Hardox and Strenx

©SSAB

The Hardox and Strenx grades are designed to 11.1 Oxy-fuel Cutting

facilitate all thermal cutting methods, including

oxy-fuel cutting, plasma cutting and laser cutting. Hardox and Strenx are easily cut by the oxy-fuel

Of course, it is also possible to use many common cutting process. Oxy-fuel cutting has almost no

cold cutting processes like abrasive water jet cutting limitations when it comes to material thickness, i.e.

and sawing. The enhanced thermal cutting material thicknesses up to 1000 mm can be cut.

performance of the Hardox and Strenx grades are Although it is possible to cut relatively thin materials,

primarily derived from their low alloy content to- the main thickness is above 20 mm. General

gether with their very low levels of impurities. features for oxy-fuel cutting can be seen in table 11.1.

Additionally, favorable properties that can be

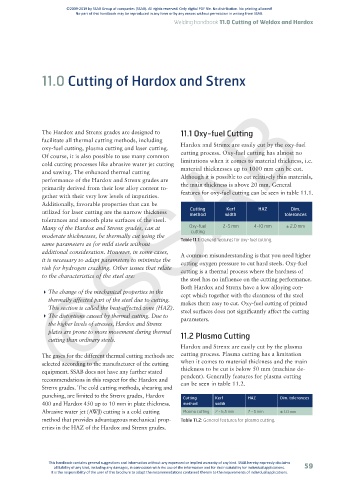

Dim.

Kerf

Cutting

utilized for laser cutting are the narrow thickness method width HAZ tolerances

tolerances and smooth plate surfaces of the steel.

Many of the Hardox and Strenx grades, can at Oxy-fuel 2-5 mm 4-10 mm ± 2.0 mm

cutting

moderate thicknesses, be thermally cut using the Table 11.1: General features for oxy-fuel cutting.

same parameters as for mild steels without

additional consideration. However, in some cases, A common misunderstanding is that you need higher

it is necessary to adapt parameters to minimize the cutting oxygen pressure to cut hard steels. Oxy-fuel

risk for hydrogen cracking. Other issues that relate cutting is a thermal process where the hardness of

to the characteristics of the steel are:

the steel has no influence on the cutting performance.

Both Hardox and Strenx have a low alloying con-

4 The change of the mechanical properties in the cept which together with the cleanness of the steel

thermally affected part of the steel due to cutting. makes them easy to cut. Oxy-fuel cutting of primed

This section is called the heat-affected zone (HAZ). steel surfaces does not significantly affect the cutting

4 The distortions caused by thermal cutting. Due to parameters.

the higher levels of stresses, Hardox and Strenx

plates are prone to more movement during thermal 11.2 Plasma Cutting

cutting than ordinary steels.

Hardox and Strenx are easily cut by the plasma

The gases for the different thermal cutting methods are cutting process. Plasma cutting has a limitation

selected according to the manufacturer of the cutting when it comes to material thickness and the main

equipment. SSAB does not have any further stated thickness to be cut is below 50 mm (machine de-

recommendations in this respect for the Hardox and pendent). Generally features for plasma cutting

can be seen in table 11.2.

Strenx grades. The cold cutting methods, shearing and

punching, are limited to the Strenx grades, Hardox Cutting Kerf HAZ Dim. tolerances

400 and Hardox 450 up to 10 mm in plate thickness. method width

Abrasive water jet (AWJ) cutting is a cold cutting Plasma cutting 2 - 6,5 mm 2 - 5 mm ± 1.0 mm

method that provides advantageous mechanical prop- Table 11.2: General features for plasma cutting.

erties in the HAZ of the Hardox and Strenx grades.

This handbook contains general suggestions and information without any expressed or implied warranty of any kind. SSAB hereby expressly disclaims

all liability of any kind, including any damages, in connection with the use of the information and for their suitability for individual applications. 59

It is the responsibility of the user of this brochure to adapt the recommendations contained therein to the requirements of individual applications.