Page 9 - LSR on Servocyclotherm G

P. 9

Introduction of Servocyclotherm G at Digboi Refinery – An Import Substitution

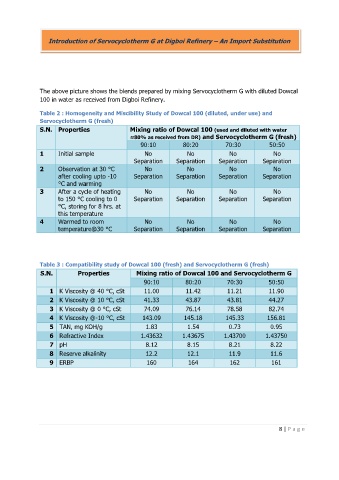

The above picture shows the blends prepared by mixing Servocyclotherm G with diluted Dowcal

100 in water as received from Digboi Refinery.

Table 2 : Homogeneity and Miscibility Study of Dowcal 100 (diluted, under use) and

Servocyclotherm G (fresh)

S.N. Properties Mixing ratio of Dowcal 100 (used and diluted with water

≈80% as received from DR) and Servocyclotherm G (fresh)

90:10 80:20 70:30 50:50

1 Initial sample No No No No

Separation Separation Separation Separation

2 Observation at 30 °C No No No No

after cooling upto -10 Separation Separation Separation Separation

°C and warming

3 After a cycle of heating No No No No

to 150 °C cooling to 0 Separation Separation Separation Separation

°C, storing for 8 hrs. at

this temperature

4 Warmed to room No No No No

temperature@30 °C Separation Separation Separation Separation

Table 3 : Compatibility study of Dowcal 100 (fresh) and Servocyclotherm G (fresh)

S.N. Properties Mixing ratio of Dowcal 100 and Servocyclotherm G

90:10 80:20 70:30 50:50

1 K Viscosity @ 40 °C, cSt 11.00 11.42 11.21 11.90

2 K Viscosity @ 10 °C, cSt 41.33 43.87 43.81 44.27

3 K Viscosity @ 0 °C, cSt 74.09 76.14 78.58 82.74

4 K Viscosity @-10 °C, cSt 143.09 145.18 145.33 156.81

5 TAN, mg KOH/g 1.83 1.54 0.73 0.95

6 Refractive Index 1.43632 1.43675 1.43700 1.43750

7 pH 8.12 8.15 8.21 8.22

8 Reserve alkalinity 12.2 12.1 11.9 11.6

9 ERBP 160 164 162 161

8 | P a g e