Page 45 - Company Profile Unit Bisnis - Kelompok 22

P. 45

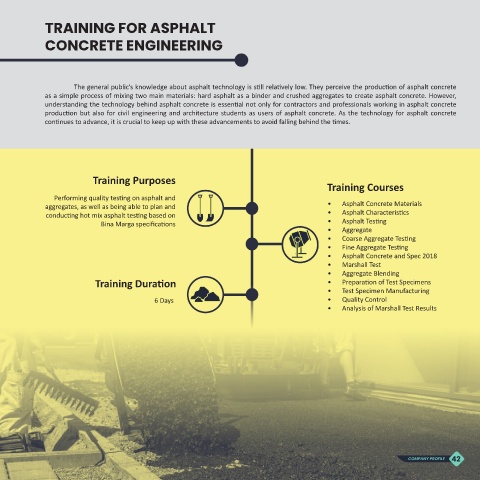

TRAINING FOR ASPHALT

CONCRETE ENGINEERING

The general public’s knowledge about asphalt technology is still relatively low. They perceive the production of asphalt concrete

as a simple process of mixing two main materials: hard asphalt as a binder and crushed aggregates to create asphalt concrete. However,

understanding the technology behind asphalt concrete is essential not only for contractors and professionals working in asphalt concrete

production but also for civil engineering and architecture students as users of asphalt concrete. As the technology for asphalt concrete

continues to advance, it is crucial to keep up with these advancements to avoid falling behind the times.

Training Purposes

Training Courses

Performing quality testing on asphalt and

aggregates, as well as being able to plan and • Asphalt Concrete Materials

conducting hot mix asphalt testing based on • Asphalt Characteristics

Bina Marga specifications • Asphalt Testing

• Aggregate

• Coarse Aggregate Testing

• Fine Aggregate Testing

• Asphalt Concrete and Spec 2018

• Marshall Test

• Aggregate Blending

Training Duration • Preparation of Test Specimens

• Test Specimen Manufacturing

6 Days • Quality Control

• Analysis of Marshall Test Results

COMPANY PROFILE 42