Page 20 - Workshop Manual - Aumark (BJ1051)

P. 20

01-14

Introduction-General Rules for Maintenance Operations

4. Removal and installation of engine intake system parts

(a) If any metal scraps are entrained into intake pipe, engine and turbocharger will be seriously

damaged.

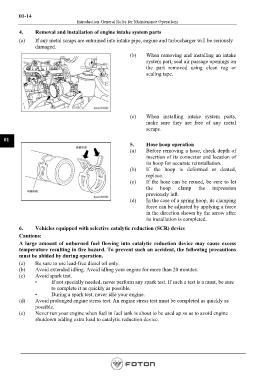

(b) When removing and installing an intake

system part, seal air passage openings on

the part removed using clean rag or

sealing tape.

(c) When installing intake system parts,

make sure they are free of any metal

scraps.

01

5. Hose hoop operation

(a) Before removing a hose, check depth of

insertion of its connector and location of

its hoop for accurate reinstallation.

(b) If the hoop is deformed or dented,

replace.

(c) If the hose can be reused, be sure to let

the hoop clamp the impression

previously left.

(d) In the case of a spring hoop, its clamping

force can be adjusted by applying a force

in the direction shown by the arrow after

its installation is completed.

6. Vehicles equipped with selective catalytic reduction (SCR) device

Cautions:

A large amount of unburned fuel flowing into catalytic reduction device may cause excess

temperature resulting in fire hazard. To prevent such an accident, the following precautions

must be abided by during operation.

(a) Be sure to use lead-free diesel oil only.

(b) Avoid extended idling. Avoid idling your engine for more than 20 minutes.

(c) Avoid spark test.

• If not specially needed, never perform any spark test. If such a test is a must, be sure

to complete it as quickly as possible.

• During a spark test, never idle your engine.

(d) Avoid prolonged engine stress test. An engine stress test must be completed as quickly as

possible.

(e) Never run your engine when fuel in fuel tank is about to be used up so as to avoid engine

shutdown adding extra load to catalytic reduction device.

Page 20