Page 33 - Gi_October2021

P. 33

igem news – yppc

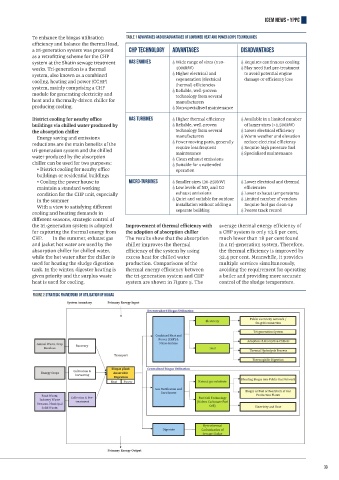

To enhance the biogas utilisation TABLE 1 ADVANTAGES AND DISADVANTAGES OF COMBINED HEAT AND POWER (CHP) TECHNOLOGIES

efficiency and balance the thermal load,

a tri-generation system was proposed CHP technology Advantages Disadvantages

as a retrofitting scheme for the CHP

system at the Shatin sewage treatment Gas engines Wide range of sizes (110- Requires continuous cooling

works. Tri-generation is a thermal 4000kW) May need fuel pre-treatment

system, also known as a combined Higher electrical and to avoid potential engine

cooling, heating and power (CCHP) cogeneration (electrical damage or efficiency loss

system, mainly comprising a CHP thermal) efficiencies

Reliable, well-proven

module for generating electricity and technology from several

heat and a thermally-driven chiller for manufacturers

producing cooling. Non-specialised maintenance

District cooling for nearby office Gas turbines Higher thermal efficiency Available in a limited number

buildings via chilled water produced by Reliable, well-proven of larger sizes (>1,500kW)

the absorption chiller technology from several Lower electrical efficiency

Energy saving and emissions manufacturers Warm weather and elevation

reductions are the main benefits of the Fewer moving parts, generally reduce electrical efficiency

tri-generation system and the chilled require less frequent Require high pressure fuel

maintenance

Specialised maintenance

water produced by the absorption Clean exhaust emissions

chiller can be used for two purposes: Suitable for unattended

• District cooling for nearby office operation

buildings or residential buildings

• Cooling the power house to Micro-turbines Smaller sizes (30-250kW) Lower electrical and thermal

maintain a standard working Low levels of NO and CO efficiencies

X

condition for the CHP unit, especially exhaust emissions Lower exhaust temperatures

in the summer Quiet and suitable for outdoor Limited number of vendors

With a view to satisfying different installation without adding a Require fuel gas clean-up

cooling and heating demands in separate building Poorer track record

different seasons, strategic control of

the tri-generation system is adopted Improvement of thermal efficiency with average thermal energy efficiency of

for capturing the thermal energy from the adoption of absorption chiller a CHP system is only 13.6 per cent,

CHP. In the summer, exhaust gas The results show that the absorption much lower than 18 per cent found

and jacket hot water are used by the chiller improves the thermal in a tri-generation system. Therefore,

absorption chiller for chilled water, efficiency of the system by using the thermal efficiency is improved by

while the hot water after the chiller is excess heat for chilled water 32.4 per cent. Meanwhile, it provides

used for heating the sludge digestion production. Comparisons of the multiple services simultaneously,

tank. In the winter, digester heating is thermal energy efficiency between avoiding the requirement for operating

given priority and the surplus waste the tri-generation system and CHP a boiler and providing more accurate

heat is used for cooling. system are shown in Figure 5. The control of the sludge temperature.

FIGURE 2 STRATEGIC FRAMEWORK OF UTILISATION OF BIOGAS

33

15/09/2021 12:12

IGEMNews_YPPC.indd 2

IGEMNews_YPPC.indd 2 15/09/2021 12:12