Page 17 - Magazine.cdr

P. 17

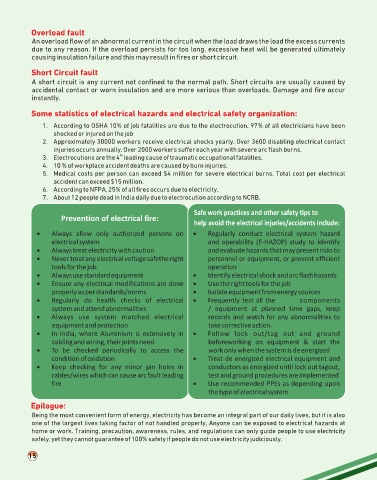

Overload fault

An overload flow of an abnormal current in the circuit when the load draws the load the excess currents

due to any reason. If the overload persists for too long, excessive heat will be generated ultimately

causing insulation failure and this may result in fires or short circuit.

Short Circuit fault

A short circuit is any current not confined to the normal path. Short circuits are usually caused by

accidental contact or worn insulation and are more serious than overloads. Damage and fire occur

instantly.

Some statistics of electrical hazards and electrical safety organization:

1. According to OSHA 10% of job fatalities are due to the electrocution. 97% of all electricians have been

shocked or injured on the job

2. Approximately 30000 workers receive electrical shocks yearly. Over 3600 disabling electrical contact

injuries occurs annually. Over 2000 workers suffer each year with severe arc flash burns.

th

3. Electrocutions are the 4 leading cause of traumatic occupational fatalities.

4. 10 % of workplace accident deaths are caused by burn injuries.

5. Medical costs per person can exceed $4 million for severe electrical burns. Total cost per electrical

accident can exceed $15 million.

6. According to NFPA, 25% of all fires occurs due to electricity.

7. About 12 people dead in India daily due to electrocution according to NCRB.

Safe work practices and other safety tips to

Prevention of electrical fire:

help avoid the electrical injuries/accidents include:

· Always allow only authorized persons on · Regularly conduct electrical system hazard

electrical system and operability (E-HAZOP) study to identify

· Always treat electricity with caution and evaluate hazards that may present risks to

· Never treat any electrical voltage safethe right personnel or equipment, or prevent efficient

tools for the job operation

· Always use standard equipment · Identify electrical shock and arc flash hazards

· Ensure any electrical modifications are done · Use the right tools for the job

properly as per standards/norms · Isolate equipment from energy sources

· Regularly do health checks of electrical · Frequently test all the components

system and attend abnormalities / equipment at planned time gaps, keep

· Always use system matched electrical records and watch for any abnormalities to

equipment and protection take corrective action.

· In India, where Aluminium is extensively in · Follow lock out/tag out and ground

cabling and wiring, their joints need. beforeworking on equipment & start the

· To be checked periodically to access the work only when the system is de energized

condition of oxidation · Treat de energized electrical equipment and

· Keep checking for any minor pin holes in conductors as energized until lock out tagout,

cables/wires which can cause arc fault leading test and ground procedures are implemented

fire · Use recommended PPEs as depending upon

the type of electrical system

Epilogue:

Being the most convenient form of energy, electricity has become an integral part of our daily lives, but it is also

one of the largest lives taking factor of not handled properly. Anyone can be exposed to electrical hazards at

home or work. Training, precaution, awareness, rules, and regulations can only guide people to use electricity

safely, yet they cannot guarantee of 100% safety if people do not use electricity judiciously.

15