Page 25 - PIGNAT catalogue 2020 GB_092020

P. 25

EVAPORATION

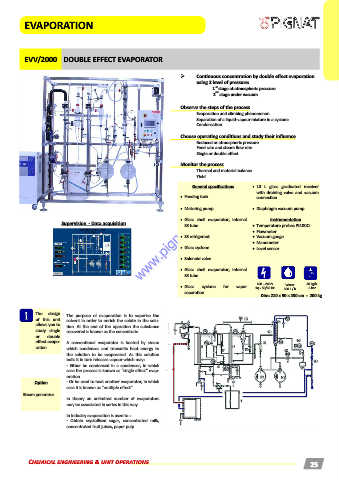

EVV/2000 DOUBLE EFFECT EVAPORATOR

➢ Continuous concentration by double effect evaporation

using 2 level of pressure:

st

1 stage at atmospheric pressure

nd

2 stage under vacuum

Observe the steps of the process

Evaporation and climbing phenomenon

Separation of a liquid-vapour mixture in a cyclone

Condensation

Choose operating conditions and study their influence

Reduced or atmospheric pressure

Feed rate and steam flow rate

Single or double effect

Monitor the process

Thermal and material balance

Yield

General specifications • 10 L glass graduated receiver

with draining valve and vacuum

• Feeding tank. • Diaphragm vacuum pump.

connection.

www.pignat.com

www.pignat.com • Vacuum gauge.

• Metering pump.

Instrumentation

Supervision - Data acquisition • Glass shell evaporator, internal • Temperature probes Pt100Ω.

SS tube.

• Flowmeter.

• SS refrigerant

• Manometer.

• Glass cyclone.

• Level sensor.

• Solenoid valve.

• Glass shell evaporator, internal

SS tube.

100 - 240 V Water 20 kg/h

• Glass cyclone for vapor 1ϕ - 50/60 Hz 500 L / h 3 bar

separation.

Dim: 210 x 90 x 230 cm - 200 kg

The design The purpose of evaporation is to vaporise the

of this unit solvent in order to enrich the solute in the solu-

allows you to tion. At the end of the operation the substance

study single recovered is known as the concentrate.

or double

effect evapo- A conventional evaporator is heated by steam

ration which condenses and transmits heat energy to

the solution to be evaporated. As this solution

boils it in turn releases vapour which may:

- Either be condensed in a condenser, in which

case the process is known as “single effect” evap-

oration.

Option - Or be used to heat another evaporator, in which

case it is known as “multiple effect”.

Steam generator.

In theory an unlimited number of evaporators

may be associated in series in this way.

In industry evaporation is used to :

- Obtain crystallised sugar, concentrated milk,

concentrated fruit juices, paper pulp.

Chemical engineering & unit operations 25